Product Description

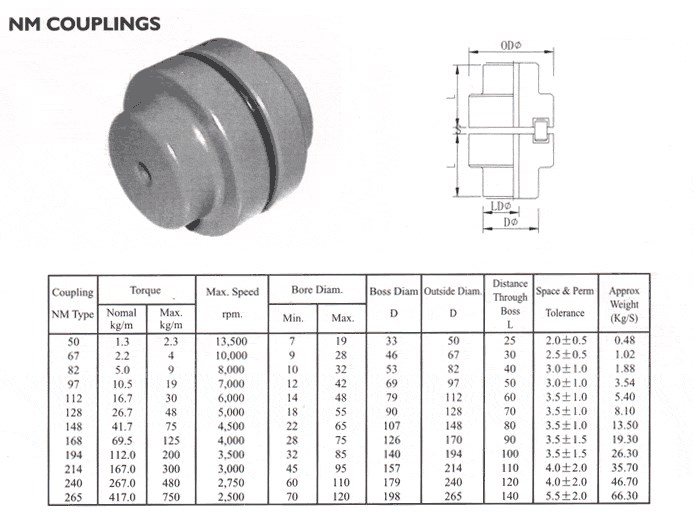

ISO DIN ANSI ASA Standard Flexible Chain Socket Nm Coupling

XIHU (WEST LAKE) DIS.HUA Chain Group is the most professional manufacturer of power transmission in China, manufacturing roller chains, industry sprockets, motorcycle sprockets, casting sprockets, different type of couplings, pulleys, taper bushes, locking devices, gears, shafts, CNC precision parts and so on. We have passed ISO9001, ISO14001, TS16949 such quality and enviroment certification.

Coupling Structure: 2 casting parts, 1 rubber gasket.

Coupling Max. Input Power: 60HP/45KW

Coupling Matched Shaft dia.: 7mm--75mm

Feature: According to the picture

1. Max torque: 125KG-M

2. Casting material, precision casting,

3. Steady, low noise on working.

4. According to GB9439, safety, reliable.

We are professional manufacture of NM coupling, we can supply coupling made by brass, SS, aluminum, steel, PP, Nylon.

Pls contact to us on free, if you need catalogue or have any questions.

| Product name | ISO DIN ANSI ASA Standard Flexible NM Coupling |

| Materials Available | 1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420 |

| 2. Steel:C45(K1045), C46(K1046),C20 | |

| 3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40) | |

| 4. Bronze: C51000, C52100, C54400, etc | |

| 5. Iron: 1213, 12L14,1215 | |

| 6. Aluminum: Al6061, Al6063 | |

| 7.OEM according to your request | |

| Surface Treatment | Annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, znic plating,yellow passivation, gold passivation, satin, Black surface painted etc. |

| Products Available | sprockt chains, pulley, shafts(axles, spline shafts, dart shafts),gears (pinions, wheels gear rack) bearing, bearing seat, bushing, coupling, lock assembly etc. |

| Processing Method | CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly |

| QC : | Technicians self-check in production,final-check before package by professional Quality inspector |

| Size | Drawings |

| Package | Wooden Case/Container and pallet, or as per customized specifications |

| Certificate | ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009 |

| Advantage | Quality first Service superior , Advanced equipment,Experienced workers,Perfect testing equipment |

| Lead Time | 15-25days samples. 30-45days offcial order |

1. Are you manufacturer or trade Company?

We are a factory founded in 1991 with trade team for international service.

2. What terms of payment you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. what is your lead time for your goods?

Normally 45 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 65 days during new year and hot season ( Jan to March).

4. Do you attend any Show?

We attend Hannover show in Germany, NMW in Austrilia, Canton fair, PTC, in China and many other special furniture shows.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Anti-Static, Corrosion-Resistant, Wear-Resistant |

| Application: | Textile Machinery, Food Machinery, Mining Equipment, Agricultural Machinery |

| Surface Treatment: | Baking Paint |

| Material: | Cast Iron |

| Size: | Nm50 67 82 97 112 128 148 168 194 214 |

| Customization: |

Available

| Customized Request |

|---|

How does a flexible coupling protect connected equipment from shock loads and vibrations?

Flexible couplings play a crucial role in protecting connected equipment from shock loads and vibrations by providing damping and isolation capabilities. When machines or mechanical systems experience sudden shock loads or vibrations, the flexible coupling acts as a buffer, absorbing and dissipating the impact, thereby reducing the transmitted forces and protecting the equipment. Here's how flexible couplings achieve this:

- Damping of Vibrations: Flexible couplings are often made from materials that exhibit damping properties. When vibrations are transmitted through the shafts, the flexible coupling's material can absorb a portion of the vibrational energy, converting it into heat. This dissipation of energy helps reduce the amplitude of the vibrations and prevents them from propagating further into the connected equipment.

- Vibration Isolation: In addition to damping vibrations, flexible couplings also offer a degree of vibration isolation. They are designed to decouple the two shafts, which means that vibrations occurring on one shaft are not directly transmitted to the other shaft. This isolation effect prevents vibrations from propagating across the entire system and minimizes the impact on sensitive equipment or nearby components.

- Shock Absorption: When the connected machinery experiences sudden shock loads, such as during a startup or abrupt changes in load, the flexible coupling can act as a shock absorber. The coupling's design allows it to deform slightly under the impact, absorbing and distributing the shock energy. This prevents the shock from being directly transferred to the connected equipment, reducing the risk of damage or premature wear.

- Misalignment Compensation: Flexible couplings are capable of compensating for misalignment between the shafts. Misalignment can lead to additional stresses and vibrations in the system. By allowing for some degree of angular, parallel, and axial misalignment, the flexible coupling reduces the forces transmitted to the connected equipment and the supporting structures.

- Reduction of Resonance Effects: Resonance is a phenomenon that occurs when the natural frequency of a system matches the frequency of external vibrations, leading to amplified vibrations. Flexible couplings can help avoid resonance effects by altering the system's natural frequency and providing some level of flexibility that damps the resonance response.

By incorporating a flexible coupling into the drivetrain or power transmission system, equipment manufacturers and operators can significantly improve the reliability and longevity of connected machinery. The coupling's ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more stable operation, reducing maintenance requirements and enhancing overall system performance.

In summary, flexible couplings act as protective elements, shielding connected equipment from shock loads and vibrations. Their ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more reliable operation of various mechanical systems.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor's life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

What materials are commonly used in manufacturing flexible couplings?

Flexible couplings are manufactured using a variety of materials, each offering different properties and characteristics suited for specific applications. The choice of material depends on factors such as the application's requirements, environmental conditions, torque capacity, and desired flexibility. Here are some of the commonly used materials in manufacturing flexible couplings:

- Steel: Steel is a widely used material in flexible couplings due to its strength, durability, and excellent torque transmission capabilities. Steel couplings are suitable for heavy-duty industrial applications with high torque requirements and harsh operating conditions.

- Stainless Steel: Stainless steel is often used to manufacture flexible couplings in environments with high corrosion potential. Stainless steel couplings offer excellent resistance to rust and other corrosive elements, making them ideal for marine, food processing, and chemical industry applications.

- Aluminum: Aluminum couplings are lightweight, have low inertia, and provide excellent balance. They are commonly used in applications where reducing weight is critical, such as aerospace and robotics.

- Brass: Brass couplings are known for their electrical conductivity and are used in applications where electrical grounding or electrical isolation is required, such as in certain industrial machinery or electronics equipment.

- Cast Iron: Cast iron couplings offer good strength and durability and are often used in industrial applications where resistance to shock loads and vibrations is necessary.

- Plastic/Polymer: Some flexible couplings use high-performance polymers or plastics, such as polyurethane or nylon. These materials provide good flexibility, low friction, and resistance to chemicals. Plastic couplings are suitable for applications where corrosion resistance and lightweight are essential.

- Elastomers: Elastomers are used as the flexible elements in many flexible couplings. Materials like natural rubber, neoprene, or urethane are commonly used as elastomer spider elements, providing flexibility and vibration damping properties.

The selection of the coupling material depends on the specific needs of the application. For instance, high-performance and heavy-duty applications may require steel or stainless steel couplings for their robustness, while applications where weight reduction is crucial may benefit from aluminum or polymer couplings. Additionally, the choice of material is influenced by factors such as temperature range, chemical exposure, and electrical requirements in the application's operating environment.

Manufacturers typically provide material specifications for their couplings, helping users make informed decisions based on the specific demands of their applications.

editor by CX 2024-05-15