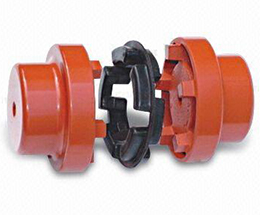

Introduction to NM Coupling for Armored Vehicle Drivetrains

Key Points:

- High Efficiency

- Strong Durability

- Precision Engineering

High Efficiency:

The NM coupling for armored vehicle drivetrains is designed to provide high efficiency in power transmission, ensuring minimal energy loss during operation.

Strong Durability:

With robust materials and advanced manufacturing processes, NM coupling offers strong durability to withstand the demanding conditions of armored vehicle drivetrains.

Precision Engineering:

Each NM coupling is precisely engineered to ensure accurate alignment and smooth operation, contributing to the overall performance of the drivetrain system.

Features of NM Coupling:

- Robust construction for long-lasting performance

- Precision machining for accurate power transmission

- Corrosion-resistant materials for reliability in harsh environments

- Easy installation and maintenance for convenience

- Compact design for space-saving integration

Applications of NM Coupling:

The NM coupling is ideal for armored vehicle drivetrains due to its:

- Ability to handle high torque loads efficiently

- Resistance to shock and vibration

- Compact size for easy integration

- Long service life for reliable performance

- Precise alignment for smooth power transmission

It can effectively transfer power in armored vehicles without loss of energy.

Ensures stable operation even in rugged terrains.

Fits seamlessly into the drivetrain system of armored vehicles.

Minimizes downtime and maintenance costs for armored vehicle fleets.

Ensures optimal performance and efficiency in armored vehicle drivetrains.

Working Principle of NM Coupling:

The NM coupling operates by...

It functions through...

By utilizing...

How to Choose the Right NM Coupling:

- Consider the torque requirements of the application

- Check the size and compatibility with existing components

- Evaluate the environmental conditions of operation

- Consult with experts for technical guidance

- Review the maintenance requirements and lifecycle costs

Ensure the NM coupling can handle the specific torque levels.

Verify that the NM coupling fits properly within the drivetrain system.

Choose a corrosion-resistant NM coupling for harsh environments.

Seek advice from professionals to select the most suitable NM coupling.

Factor in the long-term maintenance needs and costs of the NM coupling.

Maintenance of NM Coupling

Proper maintenance of NM coupling is essential to ensure...

Regular inspections and lubrication can help prevent...

By following recommended maintenance procedures, the NM coupling can provide reliable performance for a long time.

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production.

With a dedicated design and R&D team of 16 years, we offer customized products to meet global customer requirements.

All our products are CE and TUV certified, reflecting our commitment to quality and customer satisfaction.

Choose HZPT for top-notch service, high product quality, and competitive prices. Join our list of esteemed clients in Europe and America for a successful business partnership.