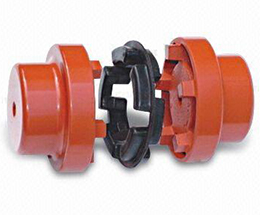

Introduction to NM Coupling for Compressors

Key Points:

- High Efficiency: NM coupling for compressors is designed to maximize energy transfer and ensure smooth operation.

- Durable Construction: These couplings are built to withstand heavy-duty usage, reducing maintenance and replacement costs.

- Precision Engineering: NM couplings are engineered with precision to ensure reliable performance in compressor applications.

Features of NM Coupling:

- High torque capacity for efficient power transmission.

- Easy installation and maintenance for convenience.

- Corrosion-resistant materials for long-term durability.

- Compact design for space-saving installation.

- Shock-absorbing properties for smooth operation.

Applications of NM Coupling:

NM coupling is ideal for compressor applications due to:

- High torque capacity to handle the power requirements of compressors.

- Corrosion-resistant materials for reliable performance in challenging environments.

- Compact design to fit in tight spaces within compressor systems.

- Easy installation and maintenance to minimize downtime.

- Shock-absorbing properties to reduce vibration and extend compressor life.

Working Principle of NM Coupling:

The NM coupling works by transmitting torque from one shaft to another while compensating for misalignment and reducing vibration. It achieves this through a combination of high-quality materials and precision engineering.

How to Choose the Right NM Coupling:

- Consider the torque requirements of your compressor system.

- Evaluate the space limitations for installation.

- Choose corrosion-resistant materials for durability.

- Ensure easy maintenance for long-term reliability.

- Select a coupling with shock-absorbing properties to protect your compressor.

Maintenance of NM Coupling

Maintaining NM coupling is essential to ensure optimal performance of your compressor system. Regular inspection, lubrication, and alignment checks can help prevent downtime and extend the lifespan of the coupling.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and 16 years of experience, we offer customized solutions to meet global customer requirements. Our commitment to quality is reflected in our CE and TUV certifications. We prioritize customer satisfaction and strive to provide the best products and services at competitive prices. Choose HZPT for high-quality couplings and a reliable partner for your business needs.