Introduction to NM Coupling for Electric Ferry Propulsion

Key Points:

- High Efficiency: NM coupling is designed to provide high efficiency in transferring power between components.

- Corrosion Resistance: With specialized materials and coatings, NM coupling offers excellent corrosion resistance in marine environments.

- Shock Absorption: The NM coupling is built to absorb shocks and vibrations, ensuring smooth operation even in rough conditions.

Product Features:

- Durable Construction: The NM coupling is made of high-quality materials for long-lasting performance.

- Precision Engineering: Each NM coupling is precision-engineered for optimal power transmission.

- Easy Installation: The NM coupling is designed for easy and quick installation, saving time and effort.

Applications of NM Coupling:

- Marine Propulsion Systems: NM coupling is ideal for electric ferry propulsion systems due to its high efficiency and corrosion resistance.

- Wind Turbines: NM coupling can also be used in wind turbines for power transmission with minimal energy loss.

- Industrial Machinery: The shock absorption capabilities of NM coupling make it suitable for various industrial machinery applications.

- Automotive Industry: NM coupling can be utilized in the automotive industry for reliable power transfer.

- Rail Transportation: NM coupling is a reliable choice for power transmission in rail transportation systems.

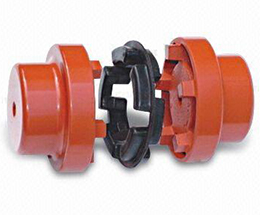

Working Principle of NM Coupling:

The NM coupling works by connecting two shafts to transmit power while allowing for misalignment and absorbing shocks and vibrations, ensuring smooth operation and minimal wear on connected components.

Choosing the Right NM Coupling:

- Consider Operating Conditions: Choose an NM coupling that can withstand the specific operating conditions of your application.

- Size and Power Rating: Ensure that the NM coupling is appropriately sized and rated for the power transmission requirements.

- Alignment Capability: Select an NM coupling with sufficient misalignment capability to accommodate any shaft misalignment.

- Maintenance Requirements: Choose an NM coupling with minimal maintenance requirements to reduce downtime and costs.

- Cost-Effectiveness: Consider the overall cost-effectiveness of the NM coupling, including initial cost and long-term maintenance.

Maintenance of NM Coupling

Regular maintenance of NM coupling is essential to ensure optimal performance and prolong its service life. This includes periodic inspection, lubrication, and alignment checks. Proper maintenance not only improves efficiency but also prevents unexpected breakdowns, reducing downtime and overall maintenance costs.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team of 16 years, we offer customized products to meet global customer requirements. Our stringent quality testing system ensures all products have CE and TUV certification. HZPT is committed to customer satisfaction, providing high-quality products and competitive prices. Our extensive product range includes various types of couplings for industrial applications. Choose HZPT for reliability, quality, and exceptional service.