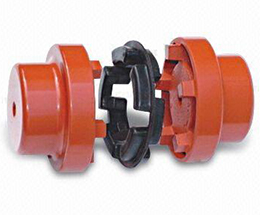

Introduction to NM Coupling for Elevators and Escalators

Key Points:

- High Precision Engineering

- Enhanced Durability

- Smooth and Efficient Power Transmission

NM coupling is specifically designed for elevators and escalators, offering exceptional precision engineering to ensure reliable performance. The enhanced durability of NM coupling ensures long-lasting operation, even under heavy loads. Its smooth and efficient power transmission capability makes it ideal for vertical transportation systems.

Features of NM Coupling:

- Corrosion-resistant materials

- Precise alignment for reduced vibration

- Low maintenance requirements

- Compact design for space-saving installation

- High torque capacity

Corrosion-resistant materials used in NM coupling ensure longevity in various operating environments. Precise alignment reduces vibration, enhancing the overall performance of elevators and escalators. With low maintenance requirements and a compact design, NM coupling is a reliable choice for vertical transportation systems with limited space.

Applications and Advantages:

- Optimal for high-rise buildings due to its high precision engineering

- Enhanced safety features ensure smooth operation in elevators and escalators

- Efficient power transmission for energy-saving performance

- Longevity and durability for continuous operation in busy settings

- Easy installation and maintenance for minimal downtime

NM coupling is the ideal choice for elevators and escalators in high-rise buildings, thanks to its precision engineering and enhanced safety features. Its efficient power transmission capabilities contribute to energy-saving performance, while its durability ensures continuous operation in busy settings. Easy installation and maintenance further reduce downtime, making NM coupling a reliable solution for vertical transportation systems.

Working Principle of NM Coupling:

The NM coupling works by transmitting torque from one shaft to another, providing a flexible connection while maintaining alignment and reducing vibration. Its design allows for smooth power transmission, enhancing the efficiency and performance of elevators and escalators.

How to Choose the Right NM Coupling:

Selection Criteria:

- Consider the torque requirements of the application

- Evaluate the operating environment for corrosion resistance

- Ensure proper shaft alignment for optimal performance

- Choose the right size and design for space constraints

- Check for compatibility with existing components

When selecting an NM coupling, it is essential to consider the torque requirements, operating environment, shaft alignment, size, and compatibility with existing components. These factors ensure the right fit for elevators and escalators, maximizing performance and longevity.

Maintenance of NM Coupling

Proper maintenance of NM coupling is crucial to ensure its continued functionality and longevity in elevators and escalators. Regular inspections, lubrication, and alignment checks can prevent premature wear and damage, leading to uninterrupted operation and safety in vertical transportation systems.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team for 16 years, we offer customized solutions to meet global customer requirements. Our comprehensive quality testing system guarantees superior products with CE and TUV certifications. HZPT prioritizes customer satisfaction, providing the highest quality products and competitive prices. Our range includes various couplings for domestic and international mechanical industries, such as radial elastic couplings, gear couplings, and membrane couplings. Choose HZPT for reliable quality and exceptional service.