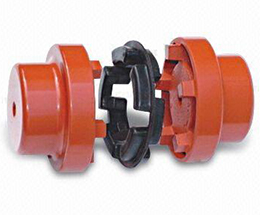

Introduction to NM Coupling for Fire Suppression Systems

Key Points:

- High Temperature Resistance

- Corrosion Resistance

- Easy Installation

High Temperature Resistance:

The NM coupling is designed to withstand high temperatures, making it ideal for fire suppression systems that may operate in extreme heat conditions. This feature ensures the coupling remains reliable and durable even in challenging environments.

Corrosion Resistance:

With a corrosion-resistant design, the NM coupling is able to withstand exposure to moisture and chemicals commonly found in fire suppression systems. This helps prolong the lifespan of the coupling and ensures consistent performance over time.

Easy Installation:

The NM coupling is designed for easy installation, allowing for quick and efficient setup in fire suppression systems. This feature helps reduce downtime during installation and maintenance, making it a convenient choice for system integrators.

Features of NM Coupling:

- Durable construction for long-term reliability

- Precision engineering for optimal performance

- Versatile design for various applications

- Compact size for space-saving installation

- Cost-effective solution for budget-conscious projects

Applications of NM Coupling:

The NM coupling is well-suited for fire suppression systems due to its specific design features:

- Resilience to high temperatures ensures consistent performance in fire-related conditions.

- Corrosion resistance prolongs the lifespan of the coupling in moisture-rich environments.

- Easy installation minimizes downtime during system setup and maintenance.

- Durable construction withstands the rigors of fire suppression system operation.

- Cost-effective solution for integrating reliable coupling in fire suppression systems.

Working Principle of NM Coupling:

The NM coupling operates by transmitting torque from one shaft to another through a flexible element, allowing for smooth power transmission while compensating for misalignment. This design ensures efficient performance and minimal wear and tear on connected equipment.

How to Choose the Right NM Coupling:

- Consider the torque requirements of your application for proper coupling selection.

- Evaluate the speed and misalignment tolerance to match with the coupling specifications.

- Choose the appropriate coupling size to ensure compatibility with the shafts and equipment.

- Check for material compatibility with the operating conditions for long-term performance.

- Consult with coupling experts for guidance on selecting the best NM coupling for your specific needs.

Maintenance of NM Coupling

Proper maintenance of NM coupling is essential to ensure reliable performance and prolong its lifespan. Regular inspection, lubrication, and alignment checks help prevent premature wear and maintain optimal coupling operation in fire suppression systems.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team for 16 years, we offer customized solutions to meet global customer requirements. Our products undergo comprehensive quality testing and hold CE and TUV certificates, reflecting our commitment to customer satisfaction and product excellence. HZPT serves a wide range of industries in Europe and America, providing top-quality products, competitive prices, and exceptional service. Choose HZPT for your coupling needs and experience our dedication to quality and customer satisfaction.