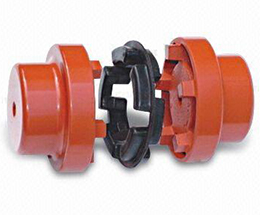

Introduction to NM Coupling for Freight Handling Systems

Key Points:

- High Load Capacity

- Precision Machining

- Corrosion Resistance

High Load Capacity:

The NM coupling is designed to withstand heavy loads, making it ideal for freight handling systems that require reliable and durable components.

Precision Machining:

Each NM coupling is intricately machined to ensure precise alignment and smooth operation, crucial for the efficient functioning of freight handling systems.

Corrosion Resistance:

With a special coating or material composition, NM couplings are resistant to corrosion, extending their lifespan and reliability in harsh industrial environments.

Features of NM Coupling:

- High strength materials

- Easy installation and maintenance

- Flexible design for various applications

- Low vibration and noise levels

- Cost-effective solution

Each feature contributes to the overall performance and longevity of the NM coupling in freight handling systems, ensuring smooth and efficient operation.

Applications of NM Coupling in Freight Handling Systems:

- Conveyor belts

- Lifting equipment

- Packaging machinery

- Cranes and hoists

- Pallet handling systems

These applications benefit from the high load capacity, precision machining, and corrosion resistance of NM couplings, leading to improved efficiency and reliability in freight handling operations.

Working Principle of NM Coupling:

The NM coupling transmits torque by connecting two shafts, allowing for the smooth transfer of power while compensating for misalignment. Its design minimizes vibration and noise, ensuring stable operation in freight handling systems.

How to Choose the Right NM Coupling:

- Consider load requirements

- Assess shaft misalignment

- Evaluate operating temperature

- Check for compatibility with other components

- Ensure proper maintenance and lubrication

Choosing the right NM coupling is crucial for optimal performance and longevity in freight handling systems, taking into account various factors to meet specific operational needs.

Maintenance of NM Coupling

Regular inspection and lubrication of the NM coupling are essential to prevent wear and ensure smooth operation in freight handling systems. Proper maintenance not only extends the lifespan of the coupling but also maintains the efficiency of the entire system.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated R&D team and a focus on quality, we provide customized solutions for global customers. Our CE and TUV certified products, along with a commitment to customer satisfaction, make us a reputable choice for coupling needs. Contact us for high-quality products, competitive prices, and excellent service.