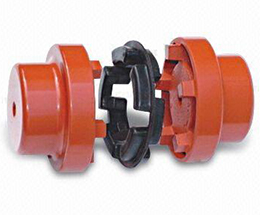

Introduction to NM Coupling for Movie Production Machinery

Key Points:

- High Precision and Stability

- Corrosion Resistance

- Easy Installation and Maintenance

High Precision and Stability:

The NM coupling is designed to provide high precision and stability in movie production machinery. Its precise construction ensures smooth operation and minimal vibration, resulting in high-quality output.

Corrosion Resistance:

With a special coating, the NM coupling offers excellent corrosion resistance, making it suitable for use in various environments, including movie production settings where exposure to different elements is common.

Easy Installation and Maintenance:

The NM coupling is easy to install and requires minimal maintenance, reducing downtime and increasing productivity in movie production machinery.

Features of NM Coupling:

- High torque transmission capacity

- Compact design for space-saving

- Customizable options available

- Optimized for high-speed applications

- Durable construction for long service life

Applications of NM Coupling:

- Ideal for precision camera rigs in movie production

- Suitable for film reel handling equipment

- Perfect for high-speed motor-driven mechanisms

- Used in audiovisual equipment for seamless operation

- Commonly applied in lighting control systems

Working Principle of NM Coupling:

The NM coupling transmits torque by connecting two shafts in movie production machinery. Its flexible elements absorb misalignments and shocks, ensuring smooth and efficient power transmission.

How to Choose the Right NM Coupling:

- Consider torque and speed requirements

- Evaluate misalignment compensation capabilities

- Choose the right size for proper fit

- Check for compatibility with movie production machinery

- Ensure corrosion resistance for longevity

Maintenance of NM Coupling

Regular inspection and lubrication are essential for maintaining the performance and longevity of NM coupling in movie production machinery. Proper maintenance ensures smooth operation and prevents unexpected downtime, saving time and cost in the long run.

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated R&D team for 16 years, we offer customized solutions to meet global customer requirements. Our products are CE and TUV certified, reflecting our commitment to quality and customer satisfaction. HZPT is known for its production strength, serving reputable clients in Europe and America with top-notch service, high product quality, and competitive prices. Choose HZPT for a reliable partner in the mechanical industry.