Introduction to NM Coupling for Optical Instruments

Key Points:

- High Precision: NM coupling for optical instruments is designed with high precision to ensure accurate and reliable performance.

- Low Backlash: This coupling offers low backlash, making it ideal for applications where precision is crucial.

- Excellent Durability: NM coupling is known for its durability and long service life, even under demanding conditions.

Features of NM Coupling:

- High Precision Machining: NM coupling is manufactured with high precision machining techniques to ensure accuracy.

- Corrosion Resistance: The coupling is resistant to corrosion, making it suitable for various environments.

- Easy Installation: NM coupling is easy to install, saving time and effort during setup.

Applications of NM Coupling:

- Optical Instruments: NM coupling is perfect for use in optical instruments due to its high precision and low backlash properties.

- Automation Systems: The coupling is suitable for automation systems where accuracy and durability are essential.

- Medical Equipment: NM coupling can be used in medical equipment for reliable and precise performance.

- Laser Technology: The coupling is ideal for applications in laser technology where precision is critical.

- Robotics: NM coupling is well-suited for robotics applications requiring high precision and durability.

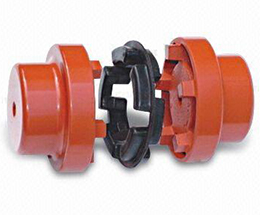

Working Principle of NM Coupling:

The NM coupling works by connecting two shafts together while allowing for a small amount of misalignment and transmitting torque between them. The coupling absorbs shocks and vibrations, reducing wear and tear on the connected equipment.

How to Choose the Right NM Coupling:

- Consider Shaft Size: Choose a coupling that matches the shaft size of the connected equipment for optimal performance.

- Check Torque Rating: Ensure that the NM coupling can handle the torque requirements of the application to prevent damage.

- Evaluate Misalignment Capability: Select a coupling that can accommodate the expected misalignment within the system.

Maintenance of NM Coupling

Maintaining your NM coupling is essential to ensure its longevity and optimal performance. Regular inspections, lubrication, and cleaning will help prevent premature wear and maintain the coupling's efficiency.

About HZPT

Established in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team of 16 years, we offer customized products to meet global customer requirements. Our products are CE and TUV certified, reflecting our commitment to quality and customer satisfaction. HZPT is known for its top-notch service, high product quality, and competitive pricing. We produce a wide range of couplings for various industrial applications, making us the ideal choice for your needs. Contact us today to discuss your requirements and experience the HZPT difference.