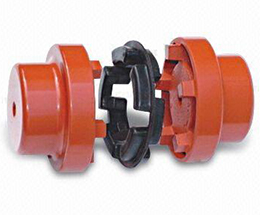

Introduction to NM Coupling for Pharmaceutical Manufacturing

Key Points:

- High Precision Transmission

- Corrosion Resistance

- Optimal Performance

High Precision Transmission

NM coupling offers high precision transmission of power, ensuring smooth and reliable operation in pharmaceutical manufacturing equipment. Its design allows for accurate torque transfer and minimal power loss.

Corrosion Resistance

With a specialized coating, NM coupling is highly resistant to corrosion, making it ideal for pharmaceutical manufacturing environments where exposure to chemicals is common. This ensures long-lasting performance and durability.

Optimal Performance

NM coupling is designed to provide optimal performance in pharmaceutical manufacturing processes. It offers high efficiency, minimal vibration, and low maintenance requirements, contributing to overall productivity and operational efficiency.

Features of NM Coupling:

- High Precision Machining

- Durable Construction

- Easy Installation

- Low Noise Operation

- Wide Temperature Range

Applications of NM Coupling:

NM coupling is suitable for pharmaceutical manufacturing applications due to the following advantages:

- Chemical Resistance: Resistant to corrosive chemicals commonly used in pharmaceutical production.

- Precision Engineering: Ensures accurate torque transmission for delicate pharmaceutical processes.

- Hygienic Design: Easy to clean and maintain for pharmaceutical industry standards.

- High Efficiency: Reduces energy consumption and enhances overall manufacturing efficiency.

- Reliable Performance: Ensures continuous operation without downtime, critical for pharmaceutical production.

Working Principle of NM Coupling:

The NM coupling operates by transmitting torque through its precision machined components, ensuring a reliable connection between two shafts. Its flexible design allows for minimal backlash and vibration, contributing to smooth power transmission.

How to Choose the Right NM Coupling:

- Consider Torque Requirements: Select a coupling that can efficiently transmit the required torque for pharmaceutical manufacturing equipment.

- Evaluate Speed and Misalignment: Choose a coupling that can accommodate the speed and misalignment of your application without compromising performance.

- Check Operating Environment: Ensure the coupling is compatible with the chemical exposure and temperature range of pharmaceutical manufacturing facilities.

- Review Maintenance Needs: Select a coupling that offers easy maintenance and long-term reliability to minimize downtime in pharmaceutical production.

- Consult with Experts: Seek advice from coupling specialists to determine the best NM coupling for your specific pharmaceutical manufacturing requirements.

Maintenance of NM Coupling

Proper maintenance of NM coupling is essential to ensure its longevity and optimal performance in pharmaceutical manufacturing equipment. Regular inspection, lubrication, and alignment checks can prevent premature wear and breakdown, minimizing downtime and maximizing productivity in pharmaceutical production processes.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team for 16 years, we offer customized solutions to meet global customer requirements. Our products undergo rigorous quality testing and hold CE and TUV certifications, reflecting our commitment to customer satisfaction and product excellence. HZPT serves a reputable client base in Europe and America, providing top-quality products, competitive pricing, and superior service. We offer a wide range of couplings for various industrial applications, including radial elastic couplings, tire couplings, universal joints, drum gear couplings, and more. Our philosophy revolves around quality, reputation, and customer satisfaction, making us the ideal choice for your coupling needs. Contact us today to discuss your requirements and experience the excellence of HZPT products.