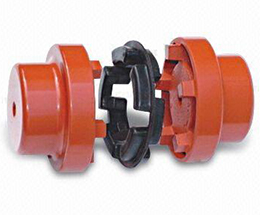

Introduction of NM Coupling for Simulation Equipment

Key Points:

- High Precision Design

- Durable Material

- Flexible Application

High Precision Design:

The NM coupling is meticulously designed to ensure high precision in its performance, making it ideal for simulation equipment that requires accurate and consistent results.

Durable Material:

Constructed from top-quality materials, the NM coupling offers durability and longevity, ensuring reliable operation even under challenging conditions in simulation equipment settings.

Flexible Application:

The NM coupling is versatile and can be used in a variety of simulation equipment, providing flexibility in design and installation options for different applications.

Features of NM Coupling:

- High torque transmission capacity

- Low maintenance requirements

- Easy installation process

- Wide range of available sizes

- Excellent shock absorption properties

Application of NM Coupling:

The NM coupling is well-suited for simulation equipment due to its:

- Ability to handle high torque loads efficiently

- Low maintenance requirements, ensuring minimal downtime

- Simple installation process, saving time and effort

- Versatility in accommodating various sizes and configurations

- Effective shock absorption capabilities for smooth operation

Working Principle of NM Coupling:

The NM coupling operates by transmitting torque from one shaft to another through its flexible elements, providing a reliable connection while allowing for misalignment and vibration absorption.

Choosing the Right NM Coupling:

- Consider torque requirements for the specific application

- Check for compatibility with shaft sizes and speeds

- Evaluate environmental conditions for material selection

- Ensure proper alignment during installation

- Consult manufacturer guidelines for optimal coupling selection

Maintenance of NM Coupling:

Regular maintenance of the NM coupling, including lubrication and inspection for wear and tear, is crucial to ensure optimal performance and prolong its lifespan. Proper maintenance helps prevent unexpected breakdowns and ensures smooth operation of simulation equipment.

About HZPT

Established in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and 16 years of experience, we offer customized solutions to meet global customer needs. Our commitment to quality is reflected in our CE and TUV certifications, ensuring product reliability. HZPT is renowned for providing top-notch service, high product quality, and competitive prices. Our extensive product range includes various types of couplings for industrial applications. Choose HZPT for exceptional quality and service – we look forward to partnering with you.