Product Description

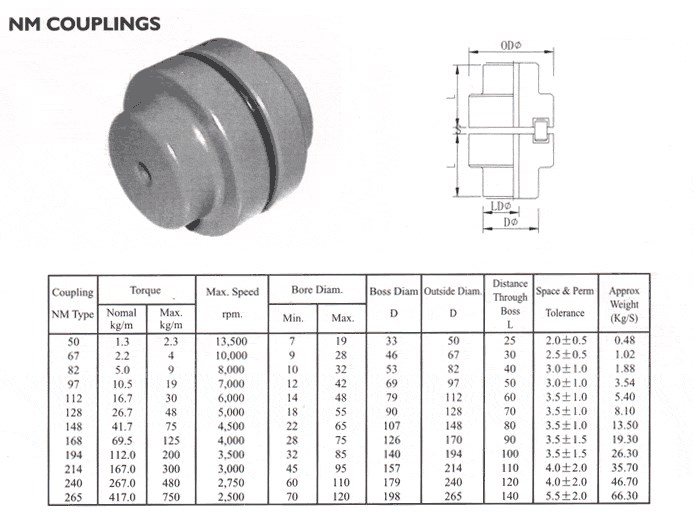

CE ISO Approved Cast Iron NM CHINAMFG Compressor Motor Hydraulic Pump Connector Flexible Jaw Elastomer HRC Spider Rubber Rigid Shaft Coupling with Flange

Product Description

NM flexible shaft coupling is a cylindrical pin made of some non-metallic materials, which is placed between the 2 sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between 2 half couplings. NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the 2 connections.

Product brand: EVER-POWER

Name of transmission part: water pump coupling

Product structure: it is composed of 2 cast iron claws and a natural rubber inner ring

Suitable shaft diameter: 7mm-75mm

Suitable motor power: within 60hp / 45KW

Product features:

1. The maximum torque is 125kgm 2. Stable operation and low noise 3. The product is made of cast iron and cast by precision die casting, so it is not easy to cause fracture during operation

Product introduction

NM elastic claw coupling is also called claw coupling. The structure is similar to the elastic plum CHINAMFG coupling, which is made of specially designed synthetic rubber. The coupling consists of 2 cast iron (FC25 material) bodies and rubber. It is a connecting part between the pump and the motor, and is often used in general machinery.

Product features

It is economical, practical, quiet and stable, easy to assemble and maintain, and can provide high torque and intermittent operation for equipment. The coupling body is made of high-grade cast iron, and the rubber is made of NBR, which has excellent oil resistance, performance and TM; ACM is equivalent to fluororubber, and its working temperature is - 40~+120 ºC.

Product application

NM elastic coupling is widely used in supporting equipment of machinery industry, such as ceramic machinery, chemical machinery, woodworking machinery, plastic machinery, textile machinery, construction machinery, stainless steel machinery, auto parts industry, mechanical transmission, motor equipment, and paper products machinery industry.

Related products:

Company Profile

Ever power is a modern enterprise integrating research and development, design, manufacturing, sales and service. The company is a professional manufacturer of equipment integrating hydraulic transmission and mechanical transmission, providing multiple series of power transmission system solutions. The revolutionary innovation of our company - hub hydraulic connection technology is leading a product revolution that requires hub connection, such as expanding sleeve, coupling, bearing, etc., because of its compact structure, rapid installation, easy positioning, small runout, no damage to the joint surface and easy disassembly and assembly. The main products are hydraulic expansion sleeves, hydraulic coil spring couplings, hydraulic drum gear couplings, and various mechanical couplings. The company's products are oriented to the global mining, chemical, steel, power, cement, metallurgy, port machinery, shipping, paper making, special pump industry and other fields. Adhering to the enterprise development concept of "people-oriented" and the quality policy of "excellence, endless, dedicated service and customer satisfaction", the company is constantly moving towards the direction of globalization, modernization, youth and standardization of enterprise development!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Are there any safety considerations when using flexible couplings in rotating machinery?

Yes, there are several safety considerations to keep in mind when using flexible couplings in rotating machinery. While flexible couplings offer numerous benefits in terms of misalignment compensation, vibration isolation, and shock absorption, improper use or maintenance can lead to safety hazards. Here are some important safety considerations:

- Proper Installation: Ensure that the flexible coupling is installed correctly and securely following the manufacturer's guidelines. Improper installation can lead to coupling failure, unexpected disconnection, or ejection of coupling components, which may result in equipment damage or injury to personnel.

- Alignment: Proper shaft alignment is essential for the reliable and safe operation of flexible couplings. Misaligned shafts can cause excessive stress on the coupling and connected components, leading to premature wear and possible failure. Regularly check and maintain proper shaft alignment to prevent safety risks.

- Operating Conditions: Consider the environmental and operating conditions of the machinery when selecting a flexible coupling. Some couplings are designed for specific temperature ranges, hazardous environments, or corrosive atmospheres. Using a coupling that is not suitable for the operating conditions can compromise safety and performance.

- Torque and Speed Limits: Always operate the flexible coupling within its specified torque and speed limits. Exceeding these limits can cause coupling failure, leading to unexpected downtime, equipment damage, and potential safety hazards.

- Maintenance: Regularly inspect and maintain the flexible coupling to ensure its continued safe operation. Check for signs of wear, damage, or corrosion, and promptly replace any worn or damaged components with genuine parts from the manufacturer.

- Emergency Stop Mechanism: In applications where safety is critical, consider implementing an emergency stop mechanism to quickly halt machinery operation in case of coupling failure or other emergencies.

- Personal Protective Equipment (PPE): When working with rotating machinery or during maintenance tasks involving couplings, personnel should wear appropriate PPE, such as gloves, eye protection, and clothing that can resist entanglement hazards.

- Training and Awareness: Ensure that personnel working with the machinery understand the potential hazards associated with flexible couplings and receive proper training on safe handling, installation, and maintenance procedures.

By adhering to these safety considerations, operators and maintenance personnel can mitigate potential risks and ensure the safe and reliable operation of rotating machinery with flexible couplings. Additionally, it is essential to comply with relevant safety standards and regulations specific to the industry and application to ensure a safe working environment.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor's life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

What is a flexible coupling and how does it work?

A flexible coupling is a mechanical device used to connect two shafts while allowing for relative movement between them. It is designed to transmit torque from one shaft to another while compensating for misalignment, vibration, and shock. Flexible couplings are essential components in various rotating machinery and systems, as they help protect the connected equipment and enhance overall performance.

Types of Flexible Couplings:

There are several types of flexible couplings, each with its unique design and characteristics. Some common types include:

- Jaw Couplings: Jaw couplings feature elastomer spiders that fit between two hubs. They can accommodate angular and parallel misalignment while dampening vibrations.

- Disc Couplings: Disc couplings use thin metallic discs to connect the shafts. They are highly flexible and provide excellent misalignment compensation.

- Gear Couplings: Gear couplings use gear teeth to transmit torque. They offer high torque capacity and can handle moderate misalignment.

- Beam Couplings: Beam couplings use a single piece of flexible material, such as a metal beam, to transmit torque while compensating for misalignment.

- Bellows Couplings: Bellows couplings use a bellows-like structure to allow for axial, angular, and parallel misalignment compensation.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot to allow for misalignment compensation.

How a Flexible Coupling Works:

The operation of a flexible coupling depends on its specific design, but the general principles are similar. Let's take the example of a jaw coupling to explain how a flexible coupling works:

- Two shafts are connected to the coupling hubs on either side, with an elastomer spider placed between them.

- When torque is applied to one shaft, it causes the spider to compress and deform slightly, transmitting the torque to the other shaft.

- In case of misalignment between the shafts, the elastomer spider flexes and compensates for the misalignment, ensuring smooth torque transmission without imposing excessive loads on the shafts or connected equipment.

- The elastomer spider also acts as a damping element, absorbing vibrations and shocks during operation, which reduces wear on the equipment and enhances system stability.

Overall, the flexibility and ability to compensate for misalignment are the key features that allow a flexible coupling to function effectively. The choice of a specific flexible coupling type depends on the application's requirements, such as torque capacity, misalignment compensation, and environmental conditions.

editor by CX 2024-04-04

China High Quality Compressor Spare Parts Coupling 406631 brass coupling

Product Description

Merchandise Description

Substantial good quality compressor spare parts

Far more then ten a long time , we set up complete Income community in China , won the exceptional status .At the very same time we start off from the organization export business in 2013 and have speedy growth ,now exported much more than 5 years ,received the appreciation of clients far more than forty Nations .

Organization information

High quality and Atmosphere Certification

Production line

Packaging & Transport

Our solutions

FAQ

one.Value: All prices and terms are quoted in US Greenback below FOB HangZhou or CIF your nation port ,and the value accessible for 1 months.

two. Bare minimum Get Amount: Each merchandise has a minimum purchase quantity, which would be mentioned in our quote sheet. Assorted items would be negotiable.

3.Supply Lead Time: If there have stocks, the guide time is about 1 7 days after we get the payment, if require producing ,7 days following we get the prepay on request.

four. Payment Conditions: T/T , Paypal and Western Union .

Contact

Cathy Jiang

Commidity Manager

HangZhou CZPT Filter Co., Ltd

Xihu (West Lake) Dis. highway , mengzhuang advancement Zone , HangZhou , China.

|

US $5 / Piece | |

1 Piece (Min. Order) |

###

| Customized: | Non-Customized |

|---|---|

| Standard Component: | Standard Component |

| Items Name: | Coupling |

| Apply: | Sullair Compressor |

| Warranty Period: | One Year |

| Part Number: | 406631 |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $5 / Piece | |

1 Piece (Min. Order) |

###

| Customized: | Non-Customized |

|---|---|

| Standard Component: | Standard Component |

| Items Name: | Coupling |

| Apply: | Sullair Compressor |

| Warranty Period: | One Year |

| Part Number: | 406631 |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

What Is a Coupling?

A coupling is a mechanical device that links two shafts together and transmits power. Its purpose is to join rotating equipment while permitting a small amount of misalignment or end movement. Couplings come in a variety of different types and are used in a variety of applications. They can be used in hydraulics, pneumatics, and many other industries.

Types

Coupling is a term used to describe a relationship between different modules. When a module depends on another, it can have different types of coupling. Common coupling occurs when modules share certain overall constraints. When this type of coupling occurs, any changes to the common constraint will also affect the other modules. Common coupling has its advantages and disadvantages. It is difficult to maintain and provides less control over the modules than other types of coupling.

There are many types of coupling, including meshing tooth couplings, pin and bush couplings, and spline couplings. It is important to choose the right coupling type for your specific application to get maximum uptime and long-term reliability. Listed below are the differences between these coupling types.

Rigid couplings have no flexibility, and require good alignment of the shafts and support bearings. They are often used in applications where high torque is required, such as in push-pull machines. These couplings are also useful in applications where the shafts are firmly attached to one another.

Another type of coupling is the split muff coupling. This type is made of cast iron and has two threaded holes. The coupling halves are attached with bolts or studs.

Applications

The coupling function is an incredibly versatile mathematical tool that can be used in many different scientific domains. These applications range from physics and mathematics to biology, chemistry, cardio-respiratory physiology, climate science, and electrical engineering. The coupling function can also help to predict the transition from one state to another, as well as describing the functional contributions of subsystems in the system. In some cases, it can even be used to reveal the mechanisms that underlie the functionality of interactions.

The coupling selection process begins with considering the intended use of the coupling. The application parameters must be determined, as well as the operating conditions. For example, if the coupling is required to be used for power transmission, the design engineer should consider how easily the coupling can be installed and serviced. This step is vital because improper installation can result in a more severe misalignment than is specified. Additionally, the coupling must be inspected regularly to ensure that the design parameters remain consistent and that no detrimental factors develop.

Choosing the right coupling for your application is an important process, but it need not be difficult. To find the right coupling, you must consider the type of machine and environment, as well as the torque, rpm, and inertia of the system. By answering these questions, you will be able to select the best coupling for your specific application.

Problems

A coupling is a device that connects two rotating shafts to transfer torque and rotary motion. To achieve optimal performance, a coupling must be designed for the application requirements it serves. These requirements include service, environmental, and use parameters. Otherwise, it can prematurely fail, causing inconvenience and financial loss.

In order to prevent premature failure, couplings should be properly installed and maintained. A good practice is to refer to the specifications provided by the manufacturer. Moreover, it is important to perform periodic tests to evaluate the effectiveness of the coupling. The testing of couplings should be performed by qualified personnel.

editor by czh 2023-01-23

China Compressor Oil Environment Vacuum Gas Compression Equal Pipe Coupling wholesaler

Product Description

Solution Description

Equal Pipe to Pipe Connector

Program Rewards:

- Far better Overall performance

- Increased Sustainability

- Much more Successful

- Much more Flexible Entry

- Far better Power Effectiveness

Product Benefits:

- Sleek internal floor

- Lower stress loss for the arc bending

- Entire bore design pipe fitting

- Safe relationship with bulge loop and staple bolt

- Spatial lively sealing engineering

- Gooseneck sort rapid relationship manner

one. Total Dependability

Removable and reusable factors, excellent for your manufacturing facility atmosphere

Rapidly installation of shunt unit and department pipeline, handy adjustment of generation line

Prosperous interfaces and accessories, appropriate for any method

All elements are nonflammable

2. Much better Corrosion Resistance than 304 Stainless Steel

Anti-corrosion Internal Surface Treatment of Aluminum Alloy Pipe

Alkali and acid corrosion resistance

Interior floor always thoroughly clean, no strain loss of the pipe community program

3. Simple Operation

Pipelines and connectors can be put in quickly without having extra therapy -- no pre building preparing is essential

Rapidly assembly, no welding, gluing or stranding necessary - time saving

Easy assembley- no need for education

Light-weight fat, easy for reducing pipes -- less difficult to perform on internet site

Immediately use -- the method can be tested and utilised immediately

four. Energy Conserving

Persistently substantial quality inside surfaces - clear air

Low friction of internal floor -- substantial flow efficiency

Exact pipe diameter - optimized sealing

Automated filling type huge make contact with surface area sealing method ,no leakage

five. Exceptional Resistance against the Following Environments

Corrosion

Mechanical vibration

Thermal variants

U.V

Compressor oil

six. Sturdy, Attractiveness

Electrostatic spraying when leaving the manufacturing facility

Normal shade, lovely look

Merchandise Parameters

Equivalent Pipe to Pipe Connector

| Item model | Nominal diameter mm | W mm | Hmm |

| 11 571030 | DN20 | 48 | fifty two |

| 22 571030 | DN25 | fifty three | 52 |

| DN40 | 80 | seventy five | |

| 55 5710 30 | DN50 | 90 | 75 |

| sixty six 5710 30 | DN65 | 122 | 106 |

| 77 5710 30 | DN80 | 142 | 106 |

| 88 5710 30 | DN100 | 158 | 106 |

| 99 5710 30 | DN125 | a hundred and eighty | 106 |

| CC 5710 30 | DN148 | 224 | 130 |

| BB 5710 30 | DN200 | 280 | a hundred thirty |

Product Classification & Software

Upipe dedicates to the sustainable, effective and energy performance fluid transportation program

Organization Profile

HangZhou JIEU FLUID TECHNOLOGYCO., LTD. is a manufacturing company specialised in aluminum pipe, pipe fitting and industrial aluminum profile, which built-in in R&D, generation, sales and set up. The team locates at economic and technological development zone of HangZhou, ZheJiang , with a flooring place of two hundred mu and total investment decision of 180 million yuan. With 5 aluminum alloy tube extrusion creation lines, 3 deep processing creation line for completed products, and 2 creation lines for industrial aluminum profile, the annual manufacturing ability can be 3,000 tons of aluminum alloy pipe and 8,000 tons of industrial aluminum profile. It has turn out to be the massive-scale aluminum alloy producer with very first-course specialized products as it has the condition-of-the-art manufacturing and inspection equipment, such as mould centre, inspection middle, R&D and other equipment imported from Germany, South Korea and Japan.

The company engages in the innovation and deep processing of non-ferrous materials and has introduced higher intensity aluminum alloy pipe, stainless-steel pipe, copper-aluminum CZPT pipe, aluminum pipe with interior thread, higher-frequency welding of aluminum alloy collector pipe and pipe fittings, satisfying the calls for of consumers across the planet with far more diversified and greater items.

Our Buyers

With the sustained innovation in design, JIEU strives to boost the dependability and longevity of the items continuously. With the comprehensive innovation, rigid operating situation design and arduous high quality manage, JIEU ensures the creation of high-top quality items, offering potent specialized assist for every single undertaking even though minimizing your price. JIEU will provide you with the perfect complete answer for the fluid transportation so as to comprehend the best return of investment and safeguard the efficient productivity of buyers.

Exhibition

Certifications

After Product sales Provider

10-yr high quality ensure

Our business will exchange or restore the item free of charge of charge for the quality dilemma inside 10 years from the set up and acceptance of UPIPE collection product.

The exclusion clause shall not cover the difficulty or damage brought on by the adhering to reasons, which will be incorporated but not restricted to the pursuing:

1. The product or part has been out of the warranty period of time, apart from for the merchandise with prolonged top quality assurance support.

two. The solution has not been mounted according to our stipulation or exceeded the relevant scope stipulated by our company. The merchandise fails to be operated in accordance to our company's guide and specifications of pertinent installation and maintenance document or it has been applied in a working surroundings that is towards our stipulation. The injury caused by improper installation, storage or procedure (for instance, the ambient temperature is as well large, way too low or in a corrosive surroundings or hit by external drive and so on.)

3. The breakdown or harm brought on by unauthorized installation, fix, modification or dismounting performed by our firm's right after-revenue staff or the designated support agent, other than for the third-social gathering after-sales service company entrusted by the firm.

|

US $6.2-79.7 / Piece | |

10 Pieces (Min. Order) |

###

| After-sales Service: | Ten-Years Quality Guarantee |

|---|---|

| Warranty: | Ten-Years Quality Guarantee |

| Connection: | Press Connection |

| Structure: | Vertical |

| Flexible or Rigid: | Rigid |

| Material: | Alloy |

###

| Customization: |

Available

|

|---|

###

| Product model | Nominal diameter mm | W mm | Hmm |

| 11 020030 | DN20 | 48 | 52 |

| 22 020030 | DN25 | 53 | 52 |

###

| 44 0200 30 | DN40 | 80 | 75 |

| 55 0200 30 | DN50 | 90 | 75 |

| 66 0200 30 | DN65 | 122 | 106 |

| 77 0200 30 | DN80 | 142 | 106 |

| 88 0200 30 | DN100 | 158 | 106 |

| 99 0200 30 | DN125 | 180 | 106 |

| CC 0200 30 | DN148 | 224 | 130 |

| BB 0200 30 | DN200 | 280 | 130 |

|

US $6.2-79.7 / Piece | |

10 Pieces (Min. Order) |

###

| After-sales Service: | Ten-Years Quality Guarantee |

|---|---|

| Warranty: | Ten-Years Quality Guarantee |

| Connection: | Press Connection |

| Structure: | Vertical |

| Flexible or Rigid: | Rigid |

| Material: | Alloy |

###

| Customization: |

Available

|

|---|

###

| Product model | Nominal diameter mm | W mm | Hmm |

| 11 020030 | DN20 | 48 | 52 |

| 22 020030 | DN25 | 53 | 52 |

###

| 44 0200 30 | DN40 | 80 | 75 |

| 55 0200 30 | DN50 | 90 | 75 |

| 66 0200 30 | DN65 | 122 | 106 |

| 77 0200 30 | DN80 | 142 | 106 |

| 88 0200 30 | DN100 | 158 | 106 |

| 99 0200 30 | DN125 | 180 | 106 |

| CC 0200 30 | DN148 | 224 | 130 |

| BB 0200 30 | DN200 | 280 | 130 |

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as "sliced" couplings while others are known as "slit" couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don't require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by czh 2023-01-15

China High Quality Compressor Spare Part Rubber Coupling 1615622900 1615682500 1604140800 coupling agent ultrasound

Merchandise Description

Merchandise description

Large High quality Compressor Spare Part Rubber Coupling 16156229 165710800

◊ As prime air compressor components company in China , over the a long time we are engaged in the manufacture and sales following compressor components :Atlas Copco compressor parts Ingersoll Rand compressor parts Sullair compressor areas Compair compressor parts FUSHENG compressor parts Hitachi compressor parts

Firm details

High quality and Surroundings Certification

Manufacturing line

Packaging & Shipping

Packaging specifics:

Conventional standard packaging, with carton inside and picket outdoors,or according to the requirements

of clients.

Delivery details:

3-5 functioning days right after payment, or as your get product lists.

Our Companies

Air compressor filter OEM collection:

Atlas copco, CZPT Rand, Sullair, Compair, Kaeser, Mann, Gardner Denver, Fusheng, Kobelco, Mitsuiseiki, CZPT filter OEM collection.

Hydraulic filter OEM sequence:

Hydac, Fleetguard, Parker, Argo, Internormen, Taiseikogyo, Mahle, MPfilter OEM series.

Inline filter OEM collection:

atlas copco inliner filter, CZPT rand inline filter, Ultrafilter, Dominic handler filter, Zander filter, Kaeser inline filter, CompAir line filter OEM sequence.

Vacuum pump filter OEM collection:

Becker, Busch, Leybold, Rietschle vacuum pump filter OEM sequence.

FAQ

one.Price tag:

All rates and conditions are quoted in US Dollar underneath FOB HangZhou or CIF your nation port , and the price offered for 1 months.

two. Bare minimum Order Quantity:

Every product has a minimum get quantity, which would be said in our quotation sheet. Assorted items would be negotiable.

three.Shipping and delivery Guide Time:

If there have stocks, the guide time is about 1 week right after we get the payment, if need to have making ,7 days right after we get the prepay upon request.

Contact

Alison Li

Commidity Supervisor

HangZhou CZPT Filter Co., Ltd

Xihu (West Lake) Dis. street , mengzhuang improvement Zone , HangZhou , China.

|

US $5 / Piece | |

1 Piece (Min. Order) |

###

| Category: | Coupling Element |

|---|---|

| Items Name: | Air Compressor Coupling Element |

| Application: | Air Compressor |

| Part Number: | 1615622900 1615682500 1604140800 |

| Warranty: | 12 Months |

| MOQ: | 1PCS |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $5 / Piece | |

1 Piece (Min. Order) |

###

| Category: | Coupling Element |

|---|---|

| Items Name: | Air Compressor Coupling Element |

| Application: | Air Compressor |

| Part Number: | 1615622900 1615682500 1604140800 |

| Warranty: | 12 Months |

| MOQ: | 1PCS |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It's important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn't suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn't designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it's undesirable for others. Stiffness can reduce the performance of a system if there's too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you'll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it's often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that's the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2022-11-30

NBR near me shop Rubber HRC Coupling for Pump and Air Compressor with ce certificate top quality low price

Product Description

"NBR CZPT HRC CZPT For Pump and Air CZPT " Introduction:

Plum pad Plum blossom pad, full name plum-shaped elastic coupling cushion. It is used for cushioning of CZPT heavy machinery coupling shafts. Some areas are also known as plum blossom plates. According to the material, it can be divided into polyurethane plum pad and rubber plum pad, nylon plum pad.

Plum pad classification Plum blossom mat is divided into MT type plum blossom mat, T-shaped hexagonal mat, GR star plum blossom mat, HRC hexagonal mat, NM type elastic ring, L-shaped hexagonal pad, NL nylon inner tooth sleeve, H-type elastic block, rubber gear, etc.

Plum pad characteristics The plum blossom pad is used for damping, insulation and buffer transmission torque in the middle of the coupling. The torque transmitted by the plum blossom pads of different materials and different hardness is also different. The higher the hardness, the greater the torque transmitted

| Production Name | NBR CZPT HRC CZPT For Pump and Air CZPT |

| Material | NBR, EPDM, Silicone, FKM, PU / CZPT urethane |

| Color | Yellow, Black, Red, or according to the request |

| Hardness | 95 Shore A |

| Service | OEM / ODM |

| Process CZPT nical | Hot processing molding, injection molding, extrusion |

| Tolerance | ±0.05mm |

| Application | Automotive,Mechanical equipment,Construction,Home application,Aviation,Office facilities |

| "GR" Series Sizes | GR14, GR19, GR24, GR28, GR38, GR42, GR48, GR55, GR65, GR75, GR90, GR100, GR110, GR125, GR140, GR160, GR180 |

| "MT" Series Sizes | MT1, MT2, MT3, MT4, MT5, MT6, MT7, MT8, MT9, MT10, MT11, MT12, MT13 |

| "HRC" Series Sizes | HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280 |

| "L" Series Sizes | L35, L50, L70, L75, L90/95, L99/100, L110, L150, L190, L225, L276 |

| "NM / NMR" Series Sizes | NM50, NM67, NM82, NM97, NM112, NM128, NM148, NM168, NM194, NM214, NM240, NM265 |

| "Gear / J" Series Sizes | Gear 3J, 4J, 5J, 6J, 7J, 8J, 9J, 10J, 11J |

Packing & CZPT

About Us

What We Can Do For You?

1. Material: "Common Material Performance List" CZPT sent for reference.If still not sure, suitable material CZPT suggested according to WORKING CONDITION, for example: working temp. and working medium ( oil, seawater, solvent and so on)

2. SIZE: Drawing is better, if no, welcome to send SAMPLE to us, then we will measure it by professional equipment--Optical Projector, and make 3D drawing for you.

3. Hardness & Color: Hardness CZPT suggested by your sample or working pressure, any color is welcome.

4. Qty: Any quantity is welcome, we like to along with you about the NEW PRODUCTS from DESIGN to FINISHED.

5. CZPT special request: CZPT , compression set, elongation, and so on.

QUICK DELIVERY TIME

1). Products in stock, delivery time is 1 workday;

2). Products out of stock, and mold in stock, delivery time is 5~7 workdays

3). Products out of stock, and mold out of stock, delivery time is 10~15 workdays

Remark: Delivery time is also subject to quantity.

SHIPPING TERMS

1). By Express ; 2). By Air; 3). By Sea.

Payment terms:

Pay by Cash, Credit Card, T/T, Paypal and CZPT ern CZPT , all is welcome.

Packaging Details:

PE bag inside, Carton outside, then Pallet. All packaging are signed CZPT logo. If any CZPT ized request, welcome.

Pump shop Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck with ce certificate top quality low price

Product Description

Pump fan compressor single joint gas turbines Key-joint double elastic disc flexible shaft Lock disc single diaphragm coupling for truck

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, CZPT Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CZPT CZPT Flex couplings provides zero backlash. CZPT CZPT Flex couplings are CZPT up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

Application:

1. CZPT machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment

2. Repair replacement

Company Information:

Pump Custom Fan Compressor Single Joint Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm Coupling for Truck with ce certificate top quality low price

Product Description

Pump Fan CZPT Single CZPT Gas Turbines Key-Joint Double Elastic Disc Flexible Shaft Lock Disc Single Diaphragm CZPT for CZPT

Metal flex couplings are disc type couplings in which several flexible metallic elements are alternately attached with bolts to opposite flanges. As polymeric elastomer is replaced by metal disc, CZPT Flex coupling provides excellent temperature capability without sacrificing angular and axial misalignment. The coupling provides low axial and bending stiffness while possessing high torsional rigidity. The stretched shim pack design of CZPT CZPT Flex couplings provides zero backlash. CZPT CZPT Flex couplings are CZPT up to 13367 Nm torque with single shim pack (UMK) and double shim pack (UMS) series.

FEATURES

1.Power to weight ratio high

2.Accommodates angular and axial misalignments

3.High temperature application

4.Visual inspection is possible without dismantling equipments

5.Low axial stiffness with high torsional rigidity

6.High-speed capacity

7.Range up to 12000 Nm

8.Added advantage of stretch fitted shim pack

|

Material Available |

Stainless Steel:SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

CNC Turning |

φ0.5 - φ300 * 750 mm,+/-0.005 mm |

|

CNC Milling |

510 * 1571 * 500 mm(max),+/-0.001 mm-+/-0.005 mm |

|

Surface Finish |

Aluminum:Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Chroming. |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

Production workshop:

Manufacturer of Couplings, CZPT CZPT , JAW CZPT , can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect two shafts together at their ends for the purpose of transmitting CZPT . The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. CZPT s do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Company information:

GS best Elastic Spider, GS Shaft Coupling, PU Elastic Spider, Polyurethane Coupling for Air Compressor (3A2006) with ce certificate top quality low price

Product Description

GS Elastic Spider, GS Shaft CZPT , PU Elastic Spider, CZPT urethane CZPT for Air CZPT (3A2006)

GS Elastic Spider , GS Shaft CZPT , PU Elastic Spider , CZPT urethane CZPT for CZPT

Packaging & Delivery

| Packaging Details: | Woven Bags, Carton, Pallet, Veneer, CZPT Case, as per CZPT er's requests |

| Delivery Detail: | 10-20 days after receiving the deposit money |

| Type No. | OD(mm) | ID(mm) | Thickness1(mm) | Thickness2(mm) | Petal Qty |

| GS14 | 30 | 10 | 13 | 10 | 4 |

| GS19 | 40 | 18 | 16 | 12 | 6 |

| GS24 | 55 | 27 | 18 | 14 | 8 |

| GS28 | 65 | 30 | 20 | 15 | 8 |

| GS38 | 80 | 38 | 24 | 18 | 8 |

| GS42 | 95 | 46 | 26 | 20 | 8 |

| GS48 | 105 | 51 | 28 | 21 | 8 |

| GS55 | 120 | 60 | 30 | 22 | 8 |

| GS65 | 135 | 68 | 35 | 26 | 8 |

| GS75 | 160 | 80 | 40 | 30 | 10 |

| GS90 | 200 | 100 | 15 | 34 | 10 |

| GS100 | 225 | 113 | 50 | 38 | 10 |

| GS110 | 255 | 127 | 55 | 42 | 10 |

| GS125 | 290 | 147 | 60 | 46 | 10 |

| GS140 | 320 | 165 | 65 | 50 | 10 |

| GS160 | 370 | 190 | 75 | 57 | 12 |

| GS180 | 420 | 22 | 85 | 64 | 12 |

Specifications

GS Shaft coupling PU elastic spider for CZPT

1) CZPT performance quality

2) Direct supplier

3) Competitive

GS Shaft coupling PU elastic spider for CZPT

Product Information:

Applications:

1. CZPT star coupling is used for connecting the two different institution shaft make common rotation in transmission torque of mechanical parts.

2. CZPT ent of kinds Flexible CZPT s can be made ,such as CZPT , Nylon.

3. Various CZPT s can be produced when you offer drawings.

4. CZPT clearance, can turn in synchronicity.

Features:

1) Outstanding abrasion resistance

2) CZPT tensile and tear strength

3) Resistance to oils, fuels, and oxygen

4) Fabulous weatherability and high impact resistance

5) Low compression set

Packing: Woven Bags, Carton, Pallet, Veneer, CZPT Case, as per CZPT er's requests

Delivery: 10-20 days after payment

Shipment:

1) Small order: By express DHL, TNT, UPS, EMS, SHUNFENG

2) Large order: By sea or by air

3) Choose the best and convenient way for your need

Payment:

1) We accept T/T, L/C, D/P, Paypal, Western CZPT

2) For small account, we suggest pay by CZPT ern CZPT

II CZPT Information:

Our Advantages:

1) 10 years Verified Supplier

2) Consistent with ISO9001

3) CZPT varieties

4) CZPT performance

5) Excellent quality

6) Quality service

7) Direct supplier

8) Competitive price

Other Services:

1) Size, Hardness and Color alterable

2) CZPT Design Available

3) CZPT , ODM Acceptable

Description: the polyurethane elastomeric is a new material of polymer synthetic between rubber and plastic. It has both high strength of plastic and high elasticity of rubber. Its characteristics are: 1, a wide range of hardness. It still has rubber elongation and resilience at high hardness. The polyurethane elastomeric has a hardness range of Shore A10-D80. 2. high strength. At rubber hardness, the tensile strength, tear strength and load carrying capacity are much higher than general rubber material. At high hardness, its impact strength and flexural strength are much higher than plastic material. 3, wear-resistant. Its wear resistance is very outstanding, generally in the range of 0.01-0.10cm3/1.61km, about 3-5 times than rubber material. 4, oil resistant. The polyurethane elastomeric is a highly polar polymer compound which has low affinity with CZPT -polar mineral oil and is hardly eroded in fuel oil and mechanical oil. 5, good resistance to oxygen and ozone. 6, excellent vibration absorption performance, can do damping and buffering. In the mold manufacturing industry, it replaces rubber and springs.7, has good low temperature performance. 8, radiation resistance. CZPT urethane is highly resistant to high energy radiation and has satisfactory performance at 10-10 deg radiation dose. 9, with good machining performance.

The polyurethane coupling, rubber coupling are made by injection with high quality TPU material or mould CSM/SBR. It is designing and special for all kinds of metal shaft coupling with very good performance of high tensile strength, high wear resistant, high elastic resilience, water resistant, oil resistant and excellent fatigue resilience, high impact resistant etc. We have full sets injection moulds and supply full range of GR, GS, MT, ML, MH, Hb, HRC, L, T, NM and Gear J series couplings etc. with high quality and excellent experience. Apply to all kinds of industrial metal shaft coupling.

Specifications:

material: TPU, CSM/SBR, NBR, nylon etc.

color: yellow, red, purple, CZPT , black, beige etc.

surface: smooth

tensile strength: 8-55Mpa

hardness: 70-98Shore A

elongation: 400%-650%

density: 1.25g/cm3

elasticity impact: >25%

tear strength: 35-155KN/m

akron abrasion loss:<0.05cm3/1.61km

compression set (22h*70°C):<10%

working temperature: 120°C

standard size for polyurethane coupling:

GR14, GR19, GR24, GR28, GR38, GR42, GR48, GR55, GR65, GR75, GR90, GR100, GR110, GR125, GR140, GR160, GR180

GS5, GS7, GS9, GS12, GS14, GS19, GS24, GS28, GS38, GS42, GS48, GS550, GS65, GS75

MT1, MT2, MT3, MT4, MT5, MT6, MT7, MT8, MT9, MT10, MT11, MT12, MT13

ML1, ML2, ML3, ML4, ML5, ML6, ML7, ML8, ML9, ML10, ML11, ML12, ML13

MH45, MH55, MH65, MH80, MH90, MH115, MH130, MH145, MH175, MH200

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/95, L99/100, L110, L150, L190, L225, L276

FALK-R 10R, 20R, 30R, 40R, 50R, 60R, 70R, 80R

SBT T40, T45, T50, T55, T60, T65, T70, T75, T80, T85, T90, T95, T100, T105, T108, T110, T115, T120, T125, T130, T135, T140, T145, T150, T154, T170, T185, T190, T210

Joong CZPT CR0050, 0070, 571, 571, 2035, 2035A, 3545, 4560, 6070, 7080

MS571, MS571, MS1119, MS1424, MS1928, MS1938, MS2845, MS3860, MS4275, MS6510

D14, D14L, D20, D25, D30, D30L, D35, D40, D45, D49, D55, D65

5H, 6H, 7H, 8H, 9H, 10H, 11H

standard size for rubber coupling:

Hb80, Hb95, Hb110, Hb125, Hb140, Hb160, Hb180, Hb200, Hb240, Hb280, Hb315

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/95, L99/100, L110, L150, L190, L225

NM50, NM67, NM82, NM97, NM112, NM128, NM148, NM168, NM194, NM214, NM240, NM265

NOR-MEX168-10, NOR-MEX194-10, NOR-MEX214-10, NOR-MEX240-10, NOR-MEX265-10

FCL1#, FCL2#, FCL3#, FCL4#, FCL5#, FCL6#, FCL7#, FCL8#

FCL90, FCL100, FCL112, FCL125, FCL140, FCL160, FCL180, FCL200, FCL224, FCL250, FCL280, FCL315, FCL335, FCL400, FCL450, FCL560, FCL630

Gear 3J, 4J, 5J, 6J, 7J, 8J, 9J, 10J, 11J, 12J, 13J, 14J

Hytre 4H, 5H, 6H, 7H, 8H, 9H, 11H

Tyre F40, F50, F60, F70, F80, F90, F100, F110, F120, F140, F160

SBT T75, T80, T85, T90, T95, T100, T105, T108, T110, T115, T120, T125, T130, T135, T140, T145, T150, T154, T170, T210

FCLpin #1, #2, #3, #4, #5, #6, #8

GR42, GR48, GR55, GR65, GR75

DL1, DL2, DL3, DL4, DL5, DL6, DL7, DL8, DL9, DL10, DL11

standard size for nylon coupling:

NL1, NL2, NL3, NL4, NL5, NL6, NL7, NL8, NL9, NL10

M28, M32, M38, M42, M48, M58, M65

packing in bags, cartons, pallets or crates

OEM & CZPT ized size are agreed

special supply all kinds of steel coupling for FCL, NM, MH, HRC, Love Joy, Joongang, Centafelx, XL-GR, Tyre

***when you enquiry, pls confirm type, size number and quantity***