Product Description

Product Description

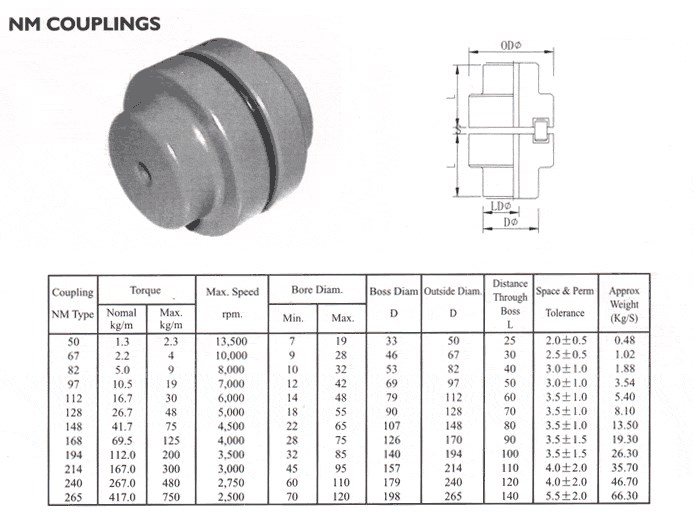

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality NM coupling.

1. Material: Cast iron, Rubber.

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing: Painted.

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

Techncial Date

| KASIN No. | Max.Torque Normal N.m | Max.speed | Bore dia. | Hub/BØ | Outside dia./A Ø | Length/L | Tolerance | Approx.Weight/Kgs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Min | Max | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| d Ø | d Ø | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 13 | 135/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

How does a flexible coupling protect connected equipment from shock loads and vibrations?Flexible couplings play a crucial role in protecting connected equipment from shock loads and vibrations by providing damping and isolation capabilities. When machines or mechanical systems experience sudden shock loads or vibrations, the flexible coupling acts as a buffer, absorbing and dissipating the impact, thereby reducing the transmitted forces and protecting the equipment. Here's how flexible couplings achieve this:

By incorporating a flexible coupling into the drivetrain or power transmission system, equipment manufacturers and operators can significantly improve the reliability and longevity of connected machinery. The coupling's ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more stable operation, reducing maintenance requirements and enhancing overall system performance. In summary, flexible couplings act as protective elements, shielding connected equipment from shock loads and vibrations. Their ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more reliable operation of various mechanical systems.

Can flexible couplings be used in applications with varying operating temperatures?Yes, flexible couplings can be used in applications with varying operating temperatures. The suitability of a flexible coupling for a specific temperature range depends on its design and the materials used in its construction. Different types of flexible couplings are available to handle a wide range of temperature conditions, making them versatile for use in various industries and environments. High-Temperature Applications: For applications with high operating temperatures, such as those found in certain industrial processes, exhaust systems, or high-temperature machinery, flexible couplings made from materials with excellent heat resistance are used. These materials may include stainless steel alloys, heat-treated steels, or specialized high-temperature elastomers. High-temperature flexible couplings are designed to maintain their mechanical properties, including flexibility and torque transmission capabilities, even at elevated temperatures. Low-Temperature Applications: Conversely, for applications in extremely cold environments or cryogenic processes, flexible couplings constructed from materials with low-temperature resistance are employed. These couplings are designed to remain flexible and functional at very low temperatures without becoming brittle or losing their ability to handle misalignment. Some low-temperature couplings may use special polymers or elastomers with excellent cold-temperature performance. Temperature Range Considerations: When selecting a flexible coupling for applications with varying operating temperatures, it is essential to consider the specific temperature range in which the coupling will operate. Some flexible couplings have a wider temperature range, allowing them to function effectively in both high and low-temperature environments. However, in extreme temperature conditions, specialized couplings may be necessary to ensure reliable performance and prevent premature failure. Manufacturer Guidelines: Manufacturers of flexible couplings provide guidelines and specifications regarding the temperature range of their products. It is crucial to consult the manufacturer's documentation to ensure that the chosen coupling is suitable for the intended operating temperature of the application. Using a coupling beyond its recommended temperature range can lead to performance issues, reduced efficiency, or even failure. Applications: Flexible couplings with varying temperature resistance find use in numerous industries, including aerospace, automotive, manufacturing, power generation, and more. Whether in high-temperature exhaust systems, low-temperature cryogenic processes, or regular industrial applications with temperature fluctuations, flexible couplings play a vital role in providing reliable power transmission and misalignment compensation. In summary, flexible couplings can be effectively used in applications with varying operating temperatures, provided that the coupling's design and material properties align with the specific temperature requirements of the application.

Can you explain the different types of flexible coupling designs available?There are several types of flexible coupling designs available, each with its unique construction and characteristics. These designs are tailored to meet specific application requirements and address different types of misalignment and torque transmission needs. Here are some of the most common types of flexible couplings:

Each flexible coupling design has its strengths and limitations, and the choice depends on factors such as the application's torque requirements, misalignment conditions, operating environment, and speed. Proper selection of the coupling type ensures optimal performance, efficiency, and reliability in various mechanical systems and rotating machinery.

L/Jaw near me shop Coupling with PU Rubber and Casting Iron Hub for Driving Machine with ce certificate top quality low price

Product Description

Product Description Features: 1. The main body is made of high-strength aluminum alloy 2. CZPT rotation interval, suitable for positive and negative rotation 3. The gel is made of polyurethane and has good wear resistance 4. Oil resistance and electrical insulation, intermediate elastomer can absorb vibration 5. Radial, angular and axial deviation compensation 6. Dismountable design for easy installation 7. Clamping screw CZPT ening method

Techncial Date

Related Products Manufacturing Application About Us Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT . In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain. In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: FCL CZPT , NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT . Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc. Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction. Certificates

Our Service 1. The questions about the coupling will be answered within 24 hours. 2. Update the procession of manufacturing. 3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment. 4. Warranty 12 months: Free replacement of defective products within 12 months. Packing Details & Delivery Inner Packing: Carton, Standard export packing or According to CZPT er's requirement Outer packing: wooden cases or According to CZPT er's requirement

Q: Are you trading company or manufacturer ?A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time. Q: How CZPT is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity. Q: Do you provide samples ? is it free or extra ?A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee. Q: What is your terms of payment ?A: 100%T/T Before shipment after inspect well If you have another question, pls feel free to contact us as below: Kasin Industries(ZheJiang ) Co.,Ltd. No.989,Guoshun Road, ZheJiang CZPT Pu CZPT Park, Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Normex near me Coupling Nm 168 with Cast Iron Hub for Motor with ce certificate top quality low price

Product Description

Product Description We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality NM coupling. 1. Material: Cast iron, CZPT . Techncial Date

Related Products Roller Chain CZPT FCL CZPT Curved Jaw CZPT Manufacturing NM couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors. About Us Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT . In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain. In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: FCL CZPT , NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT . Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc. Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction. Exhibition Certificates Our Service 1. The questions about the coupling will be answered within 24 hours. 2. Update the procession of manufacturing. 3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment. 4. Warranty 12 months: Free replacement of defective products within 12 months. Packing Details & Delivery Inner Packing: Carton, Standard export packing or According to CZPT er's requirement Outer packing: wooden cases or According to CZPT er's requirement

FAQ Q: Are you trading company or manufacturer ?A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time. Q: How CZPT is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity. Q: Do you provide samples ? is it free or extra ?A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee. Q: What is your terms of payment ?A: 100%T/T Before shipment after inspect well If you have another question, pls feel free to contact us as below: Follows Us: Kasin Industries(ZheJiang ) Co.,Ltd.No.989,Guoshun Road, ZheJiang CZPT Pu CZPT Park, Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||