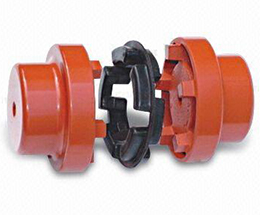

Introduction to NM Coupling for Biomass Processing Equipment

Key Points:

- High Torque Transmission

- Corrosion Resistance

- Precise Alignment

High Torque Transmission:

NM coupling is designed to efficiently transmit high levels of torque, making it ideal for biomass processing equipment that requires powerful performance.

Corrosion Resistance:

With a specialized coating, NM coupling is highly resistant to corrosion, ensuring durability and longevity even in harsh processing environments.

Precise Alignment:

The NM coupling allows for precise alignment between shafts, reducing wear and tear on equipment components and ensuring smooth operation.

Features of NM Coupling:

- High strength materials for durability

- Easy installation and maintenance

- Compact design for space-saving

- Wide range of sizes available

- Suitable for high-speed applications

Applications of NM Coupling:

NM coupling is suitable for biomass processing equipment due to its:

- Ability to handle high torque loads efficiently

- Corrosion resistance in humid and acidic environments

- Precise alignment for smooth operation

- Compact design for space-saving in processing plants

- Easy installation and maintenance for minimal downtime

Working Principle of NM Coupling:

NM coupling transmits torque by connecting two shafts together through a series of flexible elements, allowing for compensation of misalignment and vibration dampening.

How to Choose the Right NM Coupling:

- Consider torque requirements

- Evaluate shaft sizes and speeds

- Check compatibility with equipment

- Assess environmental conditions

- Consult manufacturer's recommendations

Maintenance of NM Coupling

Maintaining NM coupling is crucial for ensuring optimal performance and longevity of biomass processing equipment. Regular inspection, lubrication, and alignment checks are essential to prevent premature wear and breakdowns.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team for 16 years, we offer customized solutions to global clients with a comprehensive quality testing system from raw materials to finished products. Our CE and TUV certified products reflect our commitment to customer satisfaction, quality, and competitive pricing. Choose HZPT for reliable coupling solutions and exceptional service.