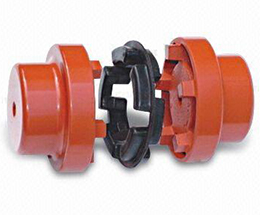

Introduction to NM Coupling for Tidal Energy Converters

Key Points:

- High Durability

- Corrosion Resistance

- Efficient Power Transmission

Application and Features:

NM coupling is designed for tidal energy converters due to its high durability, ensuring long-term performance in challenging marine environments. It is corrosion-resistant, making it ideal for saltwater applications. Additionally, the coupling provides efficient power transmission, optimizing energy conversion from tidal movements.

Product Features:

- High Durability

- Corrosion Resistance

- Efficient Power Transmission

Applications:

1. Tidal Energy Converters: NM coupling is specifically designed for tidal energy converters due to its durability and corrosion resistance in marine environments.

2. Marine Power Generation: The coupling is suitable for marine power generation applications, providing efficient power transmission for optimal energy conversion.

3. Offshore Renewable Energy: NM coupling is ideal for offshore renewable energy projects, ensuring reliable performance in harsh marine conditions.

4. Subsea Equipment: With its corrosion resistance, the coupling is suitable for subsea equipment applications, maintaining performance integrity in underwater settings.

5. Wave Energy Converters: NM coupling can be utilized in wave energy converters, offering efficient power transmission for harnessing wave power effectively.

Working Principle of NM Coupling:

NM coupling transmits torque between two shafts by connecting them with a flexible element, allowing for misalignment compensation and smooth power transmission. The coupling absorbs shocks and vibrations, reducing stress on connected equipment and ensuring reliable operation.

How to Choose the Right NM Coupling:

- Consider Torque Requirements: Select a coupling that can handle the required torque for the application.

- Evaluate Misalignment Capability: Choose a coupling with sufficient misalignment capacity to accommodate shaft misalignment.

- Corrosion Resistance: Ensure the coupling has corrosion-resistant properties for marine applications.

- Installation Space: Consider the available space for installation when choosing the coupling size and type.

- Service Life: Select a coupling with a long service life to minimize maintenance and replacement costs.

Maintenance of NM Coupling

Maintaining NM coupling involves regular inspection for wear and tear, lubrication of moving parts, and prompt replacement of damaged components. Proper maintenance is essential to ensure optimal performance and prolong the service life of the coupling, minimizing downtime and operational disruptions.

About HZPT

HZPT was established in 2006 and is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated design and R&D team for 16 years, we offer customized products to meet global customer requirements. Our comprehensive quality testing system ensures the highest product standards, with all products certified by CE and TUV. HZPT is committed to customer satisfaction, providing top-notch service, premium product quality, and competitive pricing. Our products include a wide range of couplings for various industrial applications, such as radial elastomer couplings, gear couplings, and disc couplings. Choose HZPT for high-quality, cost-effective coupling solutions, and experience the difference in our production capabilities and customer service.