Product Description

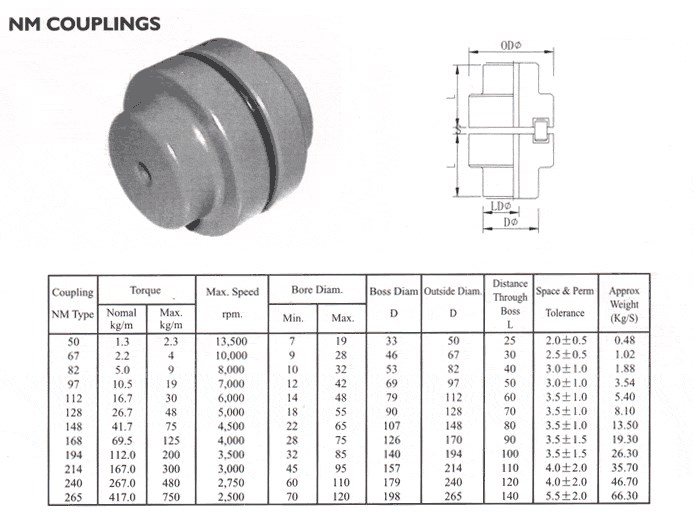

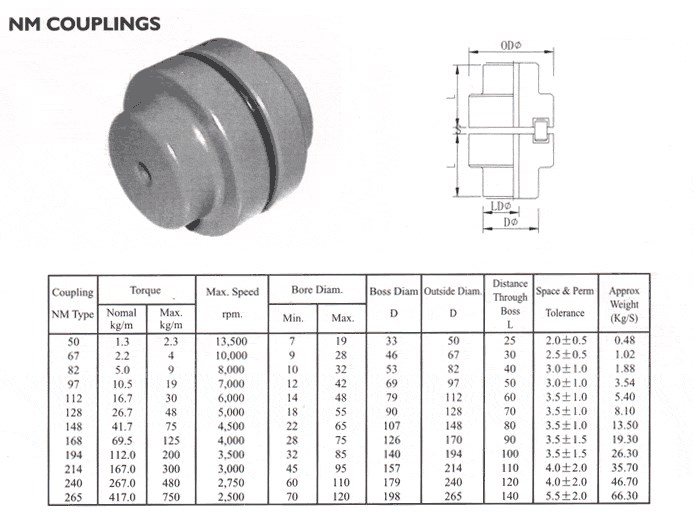

Industrial Couplings Transmission Parts Flange Rigid Pin Spacer HRC Mh Nm Fenaflex Spacer Motor Shaft Universal Half Oldham Tyre Drive Industrial Couplings

Application of Industrial Couplings

Industrial couplings are mechanical devices that are used to transmit torque and power from 1 shaft to another. They are used in a wide variety of industries, including:

- Material handling: Industrial couplings are used in material handling equipment, such as conveyor belts, elevators, and cranes.

- Power generation: Industrial couplings are used in power generation equipment, such as turbines and generators.

- Process industries: Industrial couplings are used in process industries, such as chemical plants and refineries.

- Machine tools: Industrial couplings are used in machine tools, such as lathes and milling machines.

- Transportation: Industrial couplings are used in transportation equipment, such as ships, trains, and airplanes.

There are many different types of industrial couplings, each with its own advantages and disadvantages. The type of coupling that is best suited for a particular application will depend on a number of factors, including the amount of torque that needs to be transmitted, the misalignment between the shafts, and the environmental conditions.

Some of the most common types of industrial couplings include:

- Jaw couplings: Jaw couplings are simple and rugged couplings that are easy to install and maintain. They are well suited for applications where there is a risk of misalignment.

- Gear couplings: Gear couplings are more expensive than jaw couplings, but they can transmit more torque and are less susceptible to misalignment.

- Hirth couplings: Hirth couplings are the most expensive type of industrial coupling, but they can transmit the most torque and are the least susceptible to misalignment.

Industrial couplings are an essential part of many industrial machines and systems. They play a vital role in the transmission of torque and power, and they help to ensure the safe and efficient operation of these machines and systems.

Here are some additional benefits of using industrial couplings:

- Increased efficiency: Industrial couplings can help to improve the efficiency of machines and systems by reducing friction and vibration.

- Reduced downtime: Industrial couplings can help to reduce downtime by preventing damage to machines and systems.

- Improved safety: Industrial couplings can help to improve safety by preventing machines and systems from becoming overloaded.

Overall, industrial couplings offer a number of benefits that can help to improve the efficiency, safety, and reliability of machines and systems.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer's recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer's Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling's design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling's performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

How does a flexible coupling impact the overall reliability of connected equipment?

A flexible coupling significantly impacts the overall reliability of connected equipment in several ways:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignment between connected shafts. By allowing for misalignment, the coupling reduces the stress and wear on bearings, seals, and other rotating components. This feature prevents premature failure of these components, contributing to improved reliability and extended equipment lifespan.

- Vibration Damping: Flexible couplings possess inherent damping properties due to their elastomeric or flexible elements. These elements absorb and dissipate vibrations generated during the operation of machinery. By dampening vibrations, the coupling protects the connected equipment from excessive oscillations, reducing fatigue and preventing mechanical failures. This enhanced vibration control increases the reliability of the system.

- Shock Load Absorption: In applications with sudden load variations or shock loads, such as in heavy machinery or high-speed equipment, a flexible coupling acts as a shock absorber. It can absorb and dissipate the impact energy, protecting the machinery from damage caused by sudden loads. The ability to absorb shock loads contributes to the overall reliability of the connected equipment.

- Reduced Wear and Tear: The flexibility of the coupling minimizes stress and wear on rotating equipment. It allows for slight movements and misalignments, reducing friction and stress on bearings and other critical components. This reduction in wear and tear lowers the frequency of maintenance and replacement, increasing the overall reliability of the equipment.

- Compensation for Thermal Expansion: Temperature changes in machinery can lead to thermal expansion or contraction of shafts. A flexible coupling can compensate for these thermal effects, ensuring that the machinery remains properly aligned even as temperature conditions fluctuate. This compensation prevents binding and misalignment, promoting reliable performance.

- Protection Against Overloads: Flexible couplings help protect connected equipment from overloads and torsional vibrations. They act as a mechanical fuse, disconnecting the driveline when an overload occurs, thus preventing damage to expensive machinery. This safety feature enhances the overall reliability and reduces the risk of catastrophic failures.

- Easy Maintenance and Alignment: Flexible couplings are designed for easy installation and alignment. This feature simplifies maintenance procedures, making it easier to inspect and replace couplings when necessary. Properly aligned couplings lead to improved equipment performance and longevity, enhancing overall reliability.

By compensating for misalignment, damping vibrations, absorbing shock loads, reducing wear and tear, and providing other protective features, a flexible coupling significantly improves the reliability of connected equipment. It extends the lifespan of critical components, minimizes downtime, and ensures smooth and efficient operation, making it a valuable component in various industrial applications.

Can you explain the different types of flexible coupling designs available?

There are several types of flexible coupling designs available, each with its unique construction and characteristics. These designs are tailored to meet specific application requirements and address different types of misalignment and torque transmission needs. Here are some of the most common types of flexible couplings:

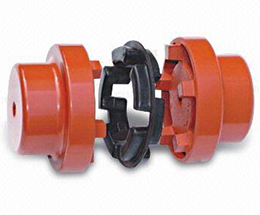

- Jaw Couplings: Jaw couplings consist of two hubs with curved jaws and an elastomer spider placed between them. The spider acts as a flexible element and can compensate for angular and parallel misalignment. Jaw couplings are widely used in various industrial applications due to their simple design and effectiveness in handling misalignment and vibration damping.

- Disc Couplings: Disc couplings use thin metallic discs with a series of alternating slits and flanges to connect the shafts. The disc coupling design allows for excellent misalignment compensation, including angular, parallel, and axial misalignment. Disc couplings are known for their high torsional stiffness and precise torque transmission capabilities.

- Gear Couplings: Gear couplings consist of toothed hubs connected by an external sleeve with gear teeth. They are well-suited for applications with high torque and moderate misalignment. Gear couplings offer good misalignment compensation and high torque capacity, making them popular in heavy-duty industrial applications.

- Beam Couplings: Beam couplings use a single piece of flexible material, often a metal beam, to connect the shafts. The material's flexibility allows for angular and axial misalignment compensation. Beam couplings are compact, lightweight, and provide low inertia, making them suitable for applications with high-speed requirements.

- Bellows Couplings: Bellows couplings consist of a bellows-like flexible structure that connects the two hubs. They can compensate for angular, parallel, and axial misalignment. Bellows couplings are known for their high torsional stiffness and ability to maintain constant velocity transmission.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot. This design allows for angular misalignment compensation while transmitting torque between the hubs. Oldham couplings are often used when electrical isolation between shafts is required.

Each flexible coupling design has its strengths and limitations, and the choice depends on factors such as the application's torque requirements, misalignment conditions, operating environment, and speed. Proper selection of the coupling type ensures optimal performance, efficiency, and reliability in various mechanical systems and rotating machinery.

editor by CX 2023-09-28

China Best Sales Industrial Couplings Transmission Parts Flange Rigid Pin Spacer HRC Mh Nm Fenaflex Spacer Motor Shaft Universal Half Oldham Tyre Drive Industrial Couplings nm couplimg

Product Description

Industrial Couplings Transmission Parts Flange Rigid Pin Spacer HRC Mh Nm Fenaflex Spacer Motor Shaft Universal Half Oldham Tyre Drive Industrial Couplings

Application of Industrial Couplings

Industrial couplings are mechanical devices that are used to transmit torque and power from 1 shaft to another. They are used in a wide variety of industries, including:

- Material handling: Industrial couplings are used in material handling equipment, such as conveyor belts, elevators, and cranes.

- Power generation: Industrial couplings are used in power generation equipment, such as turbines and generators.

- Process industries: Industrial couplings are used in process industries, such as chemical plants and refineries.

- Machine tools: Industrial couplings are used in machine tools, such as lathes and milling machines.

- Transportation: Industrial couplings are used in transportation equipment, such as ships, trains, and airplanes.

There are many different types of industrial couplings, each with its own advantages and disadvantages. The type of coupling that is best suited for a particular application will depend on a number of factors, including the amount of torque that needs to be transmitted, the misalignment between the shafts, and the environmental conditions.

Some of the most common types of industrial couplings include:

- Jaw couplings: Jaw couplings are simple and rugged couplings that are easy to install and maintain. They are well suited for applications where there is a risk of misalignment.

- Gear couplings: Gear couplings are more expensive than jaw couplings, but they can transmit more torque and are less susceptible to misalignment.

- Hirth couplings: Hirth couplings are the most expensive type of industrial coupling, but they can transmit the most torque and are the least susceptible to misalignment.

Industrial couplings are an essential part of many industrial machines and systems. They play a vital role in the transmission of torque and power, and they help to ensure the safe and efficient operation of these machines and systems.

Here are some additional benefits of using industrial couplings:

- Increased efficiency: Industrial couplings can help to improve the efficiency of machines and systems by reducing friction and vibration.

- Reduced downtime: Industrial couplings can help to reduce downtime by preventing damage to machines and systems.

- Improved safety: Industrial couplings can help to improve safety by preventing machines and systems from becoming overloaded.

Overall, industrial couplings offer a number of benefits that can help to improve the efficiency, safety, and reliability of machines and systems.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What industries commonly use flexible couplings for power transmission?

Flexible couplings are widely used in various industries for power transmission and motion control applications. Their ability to accommodate misalignment, dampen vibrations, and protect equipment from shock loads makes them valuable components in many industrial processes. Here are some of the industries that commonly utilize flexible couplings:

- Manufacturing: Flexible couplings are extensively used in manufacturing industries such as automotive, aerospace, electronics, and consumer goods production. They play a critical role in transmitting power between motors and various machinery, including conveyor systems, robots, and assembly lines.

- Oil and Gas: In the oil and gas industry, flexible couplings are used in pumps, compressors, turbines, and generators. They help transfer power in offshore platforms, refineries, pipelines, and drilling operations while compensating for the dynamic nature of these applications.

- Power Generation: Power plants, both conventional and renewable, rely on flexible couplings to transmit power from turbines and generators to electrical generators. They are used in coal-fired, natural gas, nuclear, hydroelectric, and wind power plants.

- Mining: In mining operations, flexible couplings are employed in various equipment, including conveyor systems, crushers, and large industrial pumps. They are designed to withstand the heavy loads and harsh conditions commonly found in mining environments.

- Marine: Flexible couplings are essential in marine propulsion systems, connecting engines to propellers or water jets. They also find use in shipboard machinery, auxiliary systems, and offshore applications.

- Pulp and Paper: The pulp and paper industry relies on flexible couplings in machinery used for wood processing, pulp production, papermaking, and printing processes.

- Chemical and Petrochemical: In chemical plants and petrochemical refineries, flexible couplings are utilized in pumps, mixers, agitators, and other rotating equipment to ensure efficient power transmission and protect sensitive machinery.

- Construction: The construction industry employs flexible couplings in various equipment, such as concrete pumps, cranes, excavators, and drilling machines.

- Water and Wastewater: Flexible couplings are used in water treatment plants, wastewater facilities, and irrigation systems to transfer power between motors and pumps.

- Agriculture: In agricultural machinery, flexible couplings are utilized in tractors, harvesters, and irrigation systems, enabling efficient power transmission and operation.

The versatility and adaptability of flexible couplings make them indispensable components in a wide range of industries, contributing to increased equipment reliability, reduced downtime, and improved overall system performance.

What role does a flexible coupling play in reducing downtime and maintenance costs?

A flexible coupling plays a significant role in reducing downtime and maintenance costs in industrial machinery and rotating equipment. Here are the key ways in which flexible couplings contribute to these benefits:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to accommodate misalignment between two connected shafts. Misalignment can occur due to various factors such as thermal expansion, foundation settling, or manufacturing tolerances. By allowing for misalignment, flexible couplings reduce the transmission of harmful forces and stresses to connected components, minimizing wear and preventing premature failures that could lead to costly downtime and repairs.

- Vibration Damping: Flexible couplings have inherent damping properties due to the elastomeric or flexible elements they incorporate. These elements absorb and dissipate vibration and shock loads that may arise from the operation of rotating machinery. By dampening vibrations, flexible couplings protect the connected equipment from excessive wear and fatigue, extending their service life and reducing the need for frequent maintenance or replacement.

- Shock Load Absorption: In applications where sudden loads or shocks are common, such as in heavy machinery or high-speed equipment, flexible couplings act as shock absorbers. They can absorb and dissipate the impact energy, preventing damage to the machinery and minimizing downtime caused by unexpected failures or breakdowns.

- Easy Installation and Alignment: Flexible couplings are designed for ease of installation and alignment. Unlike rigid couplings that require precise shaft alignment, flexible couplings can tolerate some degree of misalignment during installation. This feature simplifies the setup process, reduces installation time, and lowers the risk of misalignment-related issues, ultimately minimizing downtime during initial installation or replacement of couplings.

- Reduced Maintenance Frequency: The ability of flexible couplings to handle misalignment and dampen vibrations results in reduced wear on bearings, seals, and other connected components. Consequently, the frequency of maintenance intervals can be extended, reducing the need for frequent inspections and component replacements. This directly translates to lower maintenance costs and less downtime for maintenance tasks.

- Equipment Protection: By reducing the transmission of shock loads and vibrations, flexible couplings act as protective barriers for connected equipment. They help prevent catastrophic failures and subsequent damage to expensive machinery, avoiding unplanned shutdowns and costly repairs.

Overall, flexible couplings are critical components that improve the reliability and longevity of rotating equipment. Their ability to handle misalignment, dampen vibrations, and protect against shock loads contributes to reduced downtime, lower maintenance costs, and increased productivity in industrial applications.

What are the advantages of using flexible couplings in mechanical systems?

Flexible couplings offer several advantages in mechanical systems, making them essential components in various applications. Here are the key advantages of using flexible couplings:

- Misalignment Compensation: One of the primary advantages of flexible couplings is their ability to compensate for shaft misalignment. In mechanical systems, misalignment can occur due to various factors such as installation errors, thermal expansion, or shaft deflection. Flexible couplings can accommodate angular, parallel, and axial misalignment, ensuring smooth power transmission and reducing stress on the connected equipment and shafts.

- Vibration Damping: Flexible couplings act as damping elements, absorbing and dissipating vibrations and shocks generated during operation. This feature helps to reduce noise, protect the equipment from excessive wear, and enhance overall system reliability and performance.

- Torsional Flexibility: Flexible couplings provide torsional flexibility, allowing them to handle slight angular and axial deflections. This capability protects the equipment from sudden torque fluctuations, shock loads, and torque spikes, ensuring smoother operation and preventing damage to the machinery.

- Overload Protection: In case of sudden overloads or torque spikes, flexible couplings can absorb and distribute the excess torque, protecting the connected equipment and drivetrain from damage. This overload protection feature prevents unexpected failures and reduces downtime in critical applications.

- Reduce Wear and Maintenance: By compensating for misalignment and damping vibrations, flexible couplings help reduce wear on the connected equipment, bearings, and seals. This results in extended component life and reduced maintenance requirements, leading to cost savings and improved system reliability.

- Compensation for Thermal Expansion: In systems exposed to temperature variations, flexible couplings can compensate for thermal expansion and contraction, maintaining proper alignment and preventing binding or excessive stress on the equipment during temperature changes.

- Electric Isolation: Some types of flexible couplings, such as disc couplings, offer electrical isolation between shafts. This feature is beneficial in applications where galvanic corrosion or electrical interference between connected components needs to be minimized.

- Space and Weight Savings: Flexible couplings often have compact designs and low inertia, which is advantageous in applications with space constraints and where minimizing weight is crucial for performance and efficiency.

- Cost-Effectiveness: Flexible couplings are generally cost-effective solutions for power transmission and motion control, especially when compared to more complex and expensive coupling types. Their relatively simple design and ease of installation contribute to cost savings.

In summary, flexible couplings play a vital role in mechanical systems by providing misalignment compensation, vibration damping, overload protection, and torsional flexibility. These advantages lead to improved system performance, reduced wear and maintenance, and enhanced equipment reliability, making flexible couplings a preferred choice in various industrial, automotive, marine, and aerospace applications.

editor by CX 2023-08-17

Kasin wholesaler Transmission Parts Ml/Mt Shaft Coupling with Steel Material PU Rubber for Driving Motor with ce certificate top quality low price

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality ML coupling.

KASIN ML Shaft CZPT s

1. Material:the hub of the CZPT s is Cast Iron,the Elastomer is Rubbe

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain CZPT FCL CZPT Curved Jaw CZPT

Manufacturing

Applications:

ML couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT .

In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: MH COPLING, FCL CZPT , HRC CZPT ,NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT .

Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc.

With the certificate of ISO 9001 and GB/T 19001, CZPT provide top quality products at the reasonable price, to win-win situation in CZPT -terms cooperation, adhering to the slogan: "FIRST TIME, EVERY TIME".

Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction.

Exhibition

Certificates

Our Service

1. The questions about the coupling will be answered within 24 hours.

2. Update the procession of manufacturing.

3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4. Warranty 12 months: Free replacement of defective products within 12 months.

Packing Details & Delivery

Inner Packing: Carton, Standard export packing or According to CZPT er's requirement

Outer packing: wooden cases or According to CZPT er's requirement

FAQ

Q: Are you trading company or manufacturer ?

A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee.

Q: What is your terms of payment ?

A: 100%T/T Before shipment after inspect well

If you have another question, pls feel free to contact us as below:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.989,Guoshun Road, ZheJiang CZPT Pu CZPT Park,

FengXian District, ZheJiang , P.R.China, 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain.en.made-in-china.com

Transmission sales Parts Flexible Shaft Rubber Coupling Cast Iron Rn Coupling Rnb-200 for Connect Motor From Kasin Factory with ce certificate top quality low price

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality RN coupling.

KASIN RN Shaft CZPT s

1. Material:the hub of the CZPT s is Cast Iron,the Elastomer is CZPT .

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain CZPT FCL CZPT Curved Jaw CZPT

Manufacturing

Applications:

RN couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT .

In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: FCL CZPT , HRC CZPT ,NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT .

Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc.

With the certificate of ISO 9001 and GB/T 19001, CZPT provide top quality products at the reasonable price, to win-win situation in CZPT -terms cooperation, adhering to the slogan: "FIRST TIME, EVERY TIME".

Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction.

Exhibition

Certificates

Our Service

1. The questions about the coupling will be answered within 24 hours.

2. Update the procession of manufacturing.

3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4. Warranty 12 months: Free replacement of defective products within 12 months.

Packing Details & Delivery

Inner Packing: Carton, Standard export packing or According to CZPT er's requirement

Outer packing: wooden cases or According to CZPT er's requirement

FAQ

Q: Are you trading company or manufacturer ?

A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee.

Q: What is your terms of payment ?

A: 100%T/T Before shipment after inspect well

If you have another question, pls feel free to contact us as below:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.6198, Hangnan Road, ZheJiang CZPT Pu CZPT Park,

FengXian District, ZheJiang , P.R.China. Postal Code: 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain.en.made-in-china.com

Http://kasinchain.en.made-in-china.com

Kasin near me Transmission Parts Shaft Coupling Rgm Coupling Size Rgm-145 with Steel Material PU Rubber for Driving Motor From Factory Price with ce certificate top quality low price

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality RGM coupling.

KASIN RGM Shaft CZPT s

1. Material:the hub of the CZPT s is Cast Iron,the Elastomer is Rubbe

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Technical Data

Related Products

Roller Chain CZPT FCL CZPT Curved Jaw CZPT

Manufacturing

Applications:

ML couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT .

In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: MH COPLING, FCL CZPT , HRC CZPT ,NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT .

Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc.

With the certificate of ISO 9001 and GB/T 19001, CZPT provide top quality products at the reasonable price, to win-win situation in CZPT -terms cooperation, adhering to the slogan: "FIRST TIME, EVERY TIME".

Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction.

Exhibition

Certificates

Our Service

1. The questions about the coupling will be answered within 24 hours.

2. Update the procession of manufacturing.

3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4. Warranty 12 months: Free replacement of defective products within 12 months.

Packing Details & Delivery

Inner Packing: Carton, Standard export packing or According to CZPT er's requirement

Outer packing: wooden cases or According to CZPT er's requirement

FAQ

Q: Are you trading company or manufacturer ?

A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee.

Q: What is your terms of payment ?

A: 100%T/T Before shipment after inspect well

If you have another question, pls feel free to contact us as below:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.989,Guoshun Road, ZheJiang CZPT Pu CZPT Park,

FengXian District, ZheJiang , P.R.China, 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain.en.made-in-china.com

Transmission near me shop Parts Flexible Shaft Rubber Coupling Cast Iron Rn Coupling Rnb-280 for Connect Motor From Kasin Factory China with ce certificate top quality low price

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality RN coupling.

KASIN RN Shaft CZPT s

1. Material:the hub of the CZPT s is Cast Iron,the Elastomer is CZPT .

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain CZPT FCL CZPT Curved Jaw CZPT

Manufacturing

Applications:

RN couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT .

In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: FCL CZPT , HRC CZPT ,NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT .

Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc.

With the certificate of ISO 9001 and GB/T 19001, CZPT provide top quality products at the reasonable price, to win-win situation in CZPT -terms cooperation, adhering to the slogan: "FIRST TIME, EVERY TIME".

Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction.

Exhibition

Certificates

Our Service

1. The questions about the coupling will be answered within 24 hours.

2. Update the procession of manufacturing.

3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4. Warranty 12 months: Free replacement of defective products within 12 months.

Packing Details & Delivery

Inner Packing: Carton, Standard export packing or According to CZPT er's requirement

Outer packing: wooden cases or According to CZPT er's requirement

FAQ

Q: Are you trading company or manufacturer ?

A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee.

Q: What is your terms of payment ?

A: 100%T/T Before shipment after inspect well

If you have another question, pls feel free to contact us as below:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.6198, Hangnan Road, ZheJiang CZPT Pu CZPT Park,

FengXian District, ZheJiang , P.R.China. Postal Code: 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain.en.made-in-china.com

Http://kasinchain.en.made-in-china.com

Kasin shop Transmission Parts Shaft Coupling Rgm Coupling Size Rgm-50 with Steel Material PU Rubber for Driving Motor From Factory Price with ce certificate top quality low price

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in CZPT high quality RGM coupling.

KASIN RGM Shaft CZPT s

1. Material:the hub of the CZPT s is Cast Iron,the Elastomer is Rubbe

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Technical Data

Related Products

Roller Chain CZPT FCL CZPT Curved Jaw CZPT

Manufacturing

Applications:

ML couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting CZPT trolley for CZPT & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to CZPT & free line market in CZPT . With this acquisition, CZPT positioned itself as one of major parts suppliers of monorail and CZPT & free conveyor system in CZPT .

In 2005, H&H Corp., a professional manufacturer of large size conveyor chain, was purchased a portion as sharehould by CZPT , and worked as export window to all over the world, especially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, CZPT established itself machinery company/Kasin machinery(ZheJiang )Co.,Ltd., produced fleixible coupling, eg: MH COPLING, FCL CZPT , HRC CZPT ,NM CZPT , Curved Jaw CZPT , Chain CZPT andJaw CZPT .

Nowadays,Kasin is one of the biggest professional specialist of CZPT Class CZPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket CZPT vator Chain, Flexible CZPT s and 100% to oversea market, covering Japan, U.S. and CZPT p etc.

With the certificate of ISO 9001 and GB/T 19001, CZPT provide top quality products at the reasonable price, to win-win situation in CZPT -terms cooperation, adhering to the slogan: "FIRST TIME, EVERY TIME".

Our mission is to provide highest quality products at the best possible price. And in doing so, to provide an unmatched CZPT er experience and to build CZPT er CZPT and satisfaction. CZPT , Quality, Efficient, Developing, Security the five crucial components constituting CZPT , which is the key motto for all of the CZPT employees. Therefore, we keep striving to build a corporate system that is highly appreciated and we hope that you continue to select and use CZPT products with pride and satisfaction.

Exhibition

Certificates

Our Service

1. The questions about the coupling will be answered within 24 hours.

2. Update the procession of manufacturing.

3. Our professional engineer can answer technical questions,help you solve technical problems and help you choose the most suitable product according to your requirment.

4. Warranty 12 months: Free replacement of defective products within 12 months.

Packing Details & Delivery

Inner Packing: Carton, Standard export packing or According to CZPT er's requirement

Outer packing: wooden cases or According to CZPT er's requirement

FAQ

Q: Are you trading company or manufacturer ?

A: We are professionally manufacturer in CZPT and own CZPT self Forging & Casting-workshop, warmly welcome to visit CZPT factory at any time.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, it's CZPT for CZPT to submit sample for approval free of charge, however it's CZPT regulation: for new potentioal CZPT er, sample is free but CZPT er is responsilble for logistic fee.

Q: What is your terms of payment ?

A: 100%T/T Before shipment after inspect well

If you have another question, pls feel free to contact us as below:

Follows Us:

Kasin Industries(ZheJiang ) Co.,Ltd.

No.989,Guoshun Road, ZheJiang CZPT Pu CZPT Park,

FengXian District, ZheJiang , P.R.China, 201400

Tel: 86~571-8822571/8822 0571 -57152031 Fax: 86~571-8822571/8822 0571 -57152030

Http://kasinchain.en.made-in-china.com

Water Cost Pump Parts Factory Manufacturer China Standard Taper Bore Cast Iron HRC Flexible Water Pump Shaft Coupling for Electric Motor with ce certificate top quality low price

Product Description

Water Pump Parts Factory CZPT r CZPT Standard Taper Bore Cast Iron HRC Flexible Water Pump Shaft Coupling for CZPT ctric CZPT

NM couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

Related Products

Company Information

Flexible best Motor Coupling Connector Transmission Parts Best Manufacturer Industrial Stainless Steel Good Price Small Dimension Transmit Torque Anti-Rusty Coupling with ce certificate top quality low price

Product Description

Flexible CZPT CZPT Connector Transmission Parts Best CZPT r CZPT CZPT Steel CZPT Price Small Dimension Transmit Torque Anti-Rusty CZPT

Flexible CZPT CZPT

This flexible type motor coupling can connect your driving shaft with the driven shaft while it is very efficient in eliminating any misalignment to the possible extent. Minimum backlash is another great advantage of this Aluminium Flexible CZPT Coupler CZPT cal Shaft 5mm x 8mm. This Flexible coupling with the outer diameter of 19mm and the length of 25mm is machined aluminum coupling. CZPT bore diameter is 5mm and the CZPT bore diameter is of 8mm also. It comes with the spiral cut in the middle along its length which makes it flexible so they can be fit to two shafts even if they are not perfectly co-linear and will help reduce binding effects. Such couplings are also known as Beam coupling, CZPT cal coupling, Flexible coupling.

Some of the important features of flexible shaft coupling are, CZPT cal cut makes them behave like a springy in the X Y and Z linear axis but not in the rotational axis. That means that you won t get more backlash, hence they are suitable for precision CNC work. A coupling is a device which transmits CZPT and torque. CZPT s do not normally allow disconnection of shafts during operation. However, there are torque limiting couplings which can slip or disconnect when some torque limit exceeds. By careful selection, installation and maintenance of couplings, substantial savings are possible in reduced maintenance costs and downtime. It can protect the driving and driven shaft members against harmful effects because of misalignment of the shafts, sudden shock loads, shaft expansion or vibrations

Industrial manufacturer Couplings Transmission Parts Flange Rigid Pin Spacer HRC Mh Nm Fenaflex Spacer Motor Shaft Universal Half Oldham Tyre Drive Industrial Couplings with ce certificate top quality low price

Product Description

Industrial CZPT s Transmission Parts Flange Rigid Pin CZPT r HRC Mh Nm Fenaflex CZPT r CZPT Shaft CZPT Half Oldham Tyre CZPT CZPT CZPT s