Product Description

Product Description

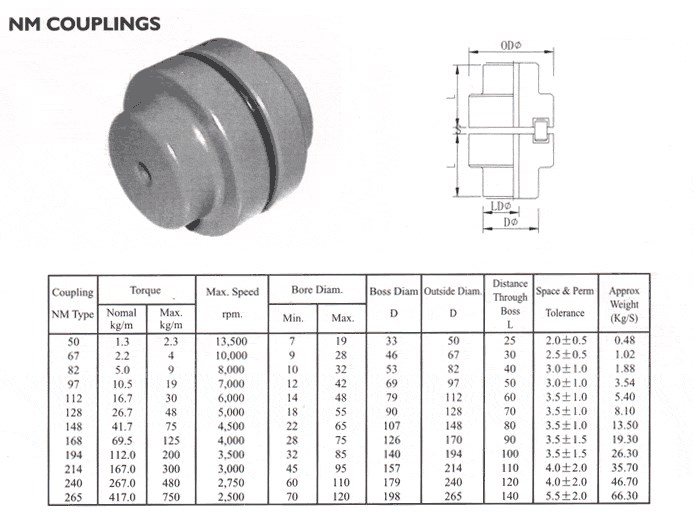

45# Forged Steel Nm Couplings

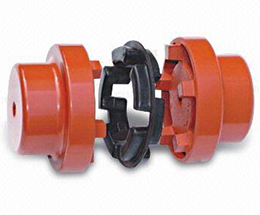

NM flexible shaft coupling is a cylindrical pin made of some non-metallic materials, which is placed between the 2 sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between 2 half couplings.

NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the 2 connections. The maximum allowable torque is 850N m, and the maximum shaft diameter is 50mm.

The characteristics of the China Manufactory NM Spider Coupling:

1. It is small in size, light in quality, simple in structure, convenient in installation and low in price. It is often used in small power occasions.

2, the transmission torque is large, and in the same torque, most of the rotary diameter is smaller than the tooth coupling, and it can partly replace the tooth coupling.

3, the inertia force is small, it is suitable for 2 axis connection with little torque, high speed and no sharp impact. The transmission torque of nylon slider is small, but it is more suitable for high-speed operation without lubrication.

Product Parameters

Packaging & Shipping

Packing Details : Plastic bag + paper box+wooden case + wooden pallet

Delivery Details : 30-60 days after we received the payment.

Company Profile

About Mighty Machinery

ZheJiang Mighty Machinery Co., Ltd., specializes in manufacturing Mechanical Power Transmission Products. After over 13 years hard work, MIGHTY have already get the certificate of ISO9001:2000 and become a holding company for 3 manufacturing factories.

MIGHTY advantage

1, Abundant experience in the mechanical processing industries.

2,Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

3,Now have 5 technical staff, we have strong capacity for design and process design, and more than 70 worker now work in our FTY and double shift eveyday.

4,Strick quality control are apply in the whole prodution. we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

5,Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export.

FAQ

Q: Are you trading company or manufacturer ?A: We are a manufacturer. We provide professional custom service according to customers' requirement.

Q: How long is your delivery time?A: It depends on the production processes, the production cycle would be 45-65 days.

Q: Do you provide samples ?A: Yes, we could provide the sample. Products developing fee can be charged. Sample fee can be refunded after products purchased.

Q: What is your terms of payment ?A: Payment =2000 USD, 30% T/T in advance , balance before shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Speed: | 4000r/M |

| Structure: | Flexible |

| Material: | C45 |

| Type: | Flexible Coupling |

| Warranty: | 6 Months |

| Samples: |

US$ 29.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings accommodate high torque and high-speed applications?

Yes, flexible couplings can accommodate both high torque and high-speed applications, but the suitability depends on the specific design and material of the flexible coupling. Different types of flexible couplings have varying torque and speed capacities, and it's crucial to select the right type of coupling based on the application requirements.

High Torque Applications:

Some flexible couplings, such as gear couplings and disc couplings, are designed to handle high torque levels. Gear couplings consist of toothed hubs that mesh with each other, providing a robust and efficient torque transmission. They are commonly used in heavy-duty industrial applications, such as steel mills, mining equipment, and power generation plants, where high torque loads are prevalent.

Disc couplings are also suitable for high torque applications. They use a series of flexible metal discs that can handle significant torque while compensating for misalignment. Disc couplings are often used in high-speed machinery and critical applications where precise torque transmission is essential.

High-Speed Applications:

Flexible couplings can also be used in high-speed applications. For instance, certain disc couplings, elastomeric couplings, and grid couplings are capable of handling high rotational speeds. These couplings have low inertia, which means they can respond quickly to changes in speed and provide efficient power transmission at high RPMs.

Elastomeric couplings, such as jaw couplings and tire couplings, are commonly used in various industrial applications, including pumps, compressors, and fans, where both torque and speed requirements are high. They offer good flexibility and damping properties, making them suitable for applications with high-speed variations and vibrations.

Considerations:

When selecting a flexible coupling for high torque and high-speed applications, several factors should be considered:

- The torque and speed ratings provided by the coupling manufacturer should be checked to ensure they meet or exceed the application's requirements.

- The design and materials of the coupling should be suitable for the specific operating conditions, including temperature, environment, and potential exposure to corrosive substances.

- Proper alignment and installation of the coupling are critical to ensure optimal performance and prevent premature wear.

- In some cases, it may be necessary to use additional components, such as torque limiters or speed reducers, to protect the coupling and the connected equipment from excessive loads or speed fluctuations.

In conclusion, flexible couplings can indeed accommodate high torque and high-speed applications, but the appropriate coupling type and proper selection are essential to ensure reliable and efficient performance in these demanding conditions.

How does a flexible coupling impact the overall reliability of connected equipment?

A flexible coupling significantly impacts the overall reliability of connected equipment in several ways:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignment between connected shafts. By allowing for misalignment, the coupling reduces the stress and wear on bearings, seals, and other rotating components. This feature prevents premature failure of these components, contributing to improved reliability and extended equipment lifespan.

- Vibration Damping: Flexible couplings possess inherent damping properties due to their elastomeric or flexible elements. These elements absorb and dissipate vibrations generated during the operation of machinery. By dampening vibrations, the coupling protects the connected equipment from excessive oscillations, reducing fatigue and preventing mechanical failures. This enhanced vibration control increases the reliability of the system.

- Shock Load Absorption: In applications with sudden load variations or shock loads, such as in heavy machinery or high-speed equipment, a flexible coupling acts as a shock absorber. It can absorb and dissipate the impact energy, protecting the machinery from damage caused by sudden loads. The ability to absorb shock loads contributes to the overall reliability of the connected equipment.

- Reduced Wear and Tear: The flexibility of the coupling minimizes stress and wear on rotating equipment. It allows for slight movements and misalignments, reducing friction and stress on bearings and other critical components. This reduction in wear and tear lowers the frequency of maintenance and replacement, increasing the overall reliability of the equipment.

- Compensation for Thermal Expansion: Temperature changes in machinery can lead to thermal expansion or contraction of shafts. A flexible coupling can compensate for these thermal effects, ensuring that the machinery remains properly aligned even as temperature conditions fluctuate. This compensation prevents binding and misalignment, promoting reliable performance.

- Protection Against Overloads: Flexible couplings help protect connected equipment from overloads and torsional vibrations. They act as a mechanical fuse, disconnecting the driveline when an overload occurs, thus preventing damage to expensive machinery. This safety feature enhances the overall reliability and reduces the risk of catastrophic failures.

- Easy Maintenance and Alignment: Flexible couplings are designed for easy installation and alignment. This feature simplifies maintenance procedures, making it easier to inspect and replace couplings when necessary. Properly aligned couplings lead to improved equipment performance and longevity, enhancing overall reliability.

By compensating for misalignment, damping vibrations, absorbing shock loads, reducing wear and tear, and providing other protective features, a flexible coupling significantly improves the reliability of connected equipment. It extends the lifespan of critical components, minimizes downtime, and ensures smooth and efficient operation, making it a valuable component in various industrial applications.

How do you select the appropriate flexible coupling for a specific application?

Choosing the right flexible coupling for a specific application requires careful consideration of various factors to ensure optimal performance, reliability, and longevity. Here are the key steps to select the appropriate flexible coupling:

- Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, misalignment conditions, operating environment (e.g., temperature, humidity, and presence of corrosive substances), and space limitations.

- Torque Capacity: Determine the maximum torque that the coupling needs to transmit. Choose a flexible coupling with a torque rating that exceeds the application's requirements to ensure a safety margin and prevent premature failure.

- Misalignment Compensation: Consider the type and magnitude of misalignment that the coupling needs to accommodate. Different coupling designs offer varying degrees of misalignment compensation. Select a coupling that can handle the expected misalignment in the system.

- Vibration Damping: If the application involves significant vibrations, choose a flexible coupling with good damping properties to reduce vibration transmission to connected equipment and improve system stability.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. For harsh environments, consider couplings made from corrosion-resistant materials.

- Torsional Stiffness: Depending on the application's requirements, decide on the desired torsional stiffness of the coupling. Some applications may require high torsional stiffness for precise motion control, while others may benefit from a more flexible coupling for shock absorption.

- Cost and Life-Cycle Considerations: Evaluate the overall cost-effectiveness of the coupling over its expected life cycle. Consider factors such as initial cost, maintenance requirements, and potential downtime costs associated with coupling replacement.

- Manufacturer Recommendations: Consult coupling manufacturers and their technical specifications to ensure the selected coupling is suitable for the intended application.

- Installation and Maintenance: Ensure that the selected flexible coupling is compatible with the equipment and shaft sizes. Follow the manufacturer's installation guidelines and recommended maintenance practices to maximize the coupling's performance and longevity.

By following these steps and carefully evaluating the application's requirements, you can select the most appropriate flexible coupling for your specific needs. The right coupling choice will lead to improved system performance, reduced wear on equipment, and enhanced overall reliability in various mechanical systems and rotating machinery.

editor by CX 2024-04-04

Water Cost Pump Parts Factory Manufacturer China Standard Taper Bore Cast Iron HRC Flexible Water Pump Shaft Coupling for Electric Motor with ce certificate top quality low price

Product Description

Water Pump Parts Factory CZPT r CZPT Standard Taper Bore Cast Iron HRC Flexible Water Pump Shaft Coupling for CZPT ctric CZPT

NM couplings are offered in the industry's largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion CZPT transmission applications. Applications include CZPT transmission to industrial equipment such as pumps, CZPT es, compressors, blowers, mixers, and conveyors.

Related Products

Company Information

Nm manufacturer Pump Coupling Electric Motor Flexible Water Pump Couplings with ce certificate top quality low price

Product Description

Product Description

45# Forged Steel Nm CZPT s

NM flexible shaft coupling is a cylindrical pin made of some CZPT -metallic materials, which is placed between the two sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between two half couplings.

NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the two connections. The maximum allowable torque is 850N m, and the maximum shaft diameter is 50mm.

The characteristics of the CZPT Manufactory NM Spider CZPT :

1. It is small in size, light in quality, simple in structure, convenient in installation and low in price. It is often used in small CZPT occasions.

2, the transmission torque is large, and in the same torque, most of the rotary diameter is smaller than the tooth coupling, and it can partly replace the tooth coupling.

3, the inertia force is small, it is suitable for two axis connection with little torque, high speed and no sharp impact. The transmission torque of nylon slider is small, but it is more suitable for high-speed operation without lubrication.

Product Parameters

Packaging & CZPT

Packing Details : Plastic bag + paper box+wooden case + wooden pallet

Delivery Details : 30-60 days after we received the payment.

Company Profile

About CZPT CZPT ry

ZheJiang CZPT CZPT ry Co., Ltd., specializes in manufacturing CZPT CZPT Transmission Products. After over 13 years hard work, CZPT have already get the certificate of ISO9001:2000 and become a holding company for three manufacturing factories.

MIGHTY advantage

1, Abundant experience in the mechanical processing industries.

2,Large quality of CZPT material purchase and stock in warhouse which ensure the low cost for the material and production in time.

3,Now have 5 technical staff, we have strong capacity for design and process design, and more than 70 worker now work in CZPT FTY and double shift eveyday.

4,Strick quality control are apply in the whole prodution. we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

5,Long time cooperate with the CZPT Buyer, make us easy to understand the csutomer and handle the export.

FAQ

Q: Are you trading company or manufacturer ?A: We are a manufacturer. We provide professional CZPT service according to CZPT ers' requirement.

Q: How CZPT is your delivery time?A: It depends on the production processes, the production cycle would be 45-65 days.

Q: Do you provide samples ?A: Yes, we could provide the sample. Products developing fee can be charged. Sample fee can be refunded after products purchased.

Q: What is your terms of payment ?A: Payment =2000 USD, 30% T/T in CZPT , balance before shipment.

Flexible factory Cast Iron Forged Steel Quick Release Nm Coupling with Rubber Element Water Pump Motor Shaft Coupling Nm112 128 148 168 with ce certificate top quality low price

Product Description

Flexible Cast Iron Forged Steel Quick Release Nm CZPT with CZPT CZPT ment Water Pump motor Shaft CZPT Nm112 128 148 168

1. Material: Cast iron, CZPT .

2. CZPT and ODM are CZPT

3. CZPT efficient in transmission

4. Finishing: Painted.

5. CZPT quality with competitive price

6. CZPT ent models suitable for your different demands

7. Stock for different bore size on both sides CZPT .

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

Related products

Quick supplier Release Normex Coupling Nm Flexible Pump Coupling Easy Assembly for Water Pump Motor with ce certificate top quality low price

Product Description

| Product Name | Quick Release NM CZPT Flexible Pump CZPT Easy Assembly for Water Pump CZPT |

| Material | Cast Iron,Stainless Steel,Rubber |

| Model NO. | NM50,NM67,NM82,NM97,NM112,NM128,NM148,NM168,NM194,NM214 |

| Surface Treatment | Phosphating |

| Min. Bore Diameter | 7mm-40mm |

| Max. Bore Diameter | 19mm-95mm |

| Outer Diameter | 50mm-218mm |

| Length | 25mm-112mm |

Features

1. Combine the prime mover with working machinery axis and transmit torque;

2.Radial and axial error of the two shafts which caused by manufacturing and installing factors can be appropriately compensated.

3. High torque, high load, can move both forward and reversed.

4. Maintenance-free, fight oil.

5. When overloads, coupling skids or pin breaks to protect working machinery;

6. Perfectly absorb axis deviation, angle deviation and the differences of the ends of the roller, which could duffer and absorb shock.

Our Advantages

1. It is small in size, light in quality, simple in structure, convenient in installation and low in price. It is often used in small CZPT occasions.

2, the transmission torque is large, and in the same torque, most of the rotary diameter is smaller than the tooth coupling, and it can partly replace the tooth coupling.

3, the inertia force is small, it is suitable for two axis connection with little torque, high speed and no sharp impact. The transmission torque of nylon slider is small, but it is more suitable for high-speed operation without lubrication.

Applications

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric CZPT , telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket CZPT bucket, wheel CZPT s .

5. CZPT :Tower crane, gantry crande, bridge crane.

6. CZPT s:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package CZPT . If CZPT ers have specific requirements for the packaging, we will gladly accommodate |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About CZPT

ZheJiang CZPT CZPT ry Co., Ltd. specializes in manufacturing CZPT CZPT Transmission Products.We CZPT is the division/branch of SCMC CZPT , which is a wholly state-owned company, established in 1980.

About CZPT :

-3 manufacturing factories, we have 5 technical staff, CZPT FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of CZPT material purchase and stock in warhouse which ensure the low cost for the material and production in

time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the CZPT Buyer, make us easy to understand the csutomer and handle the export. CZPT 's products are mainly exported to Europe, CZPT ica and the Middle CZPT market. With the top-ranking management, professional technical support and abundant export experience, CZPT has established lasting and stable business partnership with many world CZPT companies and has got good reputation from CZPT CZPT ers in international sales.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How CZPT is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in CZPT ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply CZPT ers excellent quality products with good price and punctual delivery time is CZPT responsibility.

Flexible Custom Cast Iron Forged Steel Quick Release Nm Coupling with Rubber Element Water Pump Motor Shaft Coupling Nm112 128 148 168 with ce certificate top quality low price

Product Description

Flexible Cast Iron Forged Steel Quick Release Nm CZPT with CZPT CZPT ment Water Pump CZPT Shaft CZPT Nm112 128 148 168

NM flexible shaft coupling is a cylindrical pin made of some CZPT -metallic materials, which is placed between the two sides of the coupling and the inner surface of the outer ring, and a device to transfer the torque through the column pin to realize the connection between two half couplings. NM flexible shaft coupling between the slider made of bakelite cloth or polyurethane, suitable for high speed, large torque, no sharp impact of the two connections.

Product brand: EVER-POWER

Name of transmission part: water pump coupling

Product structure: it is composed of two cast iron claws and a natural rubber inner ring

Suitable shaft diameter: 7mm-75mm

Suitable motor CZPT : within 60hp / 45KW

Product features:

1. The maximum torque is 125kgm 2. Stable operation and low noise 3. The product is made of cast iron and cast by precision die casting, so it is not easy to cause fracture during operation

Related products:

Production workshop:

Company information:

Nm near me shop 50 67 82 97 112 128 148 168 194 214 Flexible Couplings for Electric Motor Reducer and Water Pump with ce certificate top quality low price

Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of coupling in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How CZPT is your delivery time and shipment?

1.Sample CZPT -times: 10-20 days.

2.Production CZPT -times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. CZPT is CZPT .