Product Description

Rigid Coupling Transmission Parts Couplings Shaft Metal Stainless Steel Tooth Drum Curve NM Chain Shaft Fexible Type of Rubber Best Manufacturers Rigid Coupling

Application of Rigid Coupling

Rigid couplings are used to connect 2 shafts that are perfectly aligned. They are made up of 2 flanges, 1 mounted on each shaft. The flanges are then bolted together, which ensures that the shafts are held in place and cannot move relative to each other.

Rigid couplings are used in a wide variety of applications, including:

- Machine tools: Rigid couplings are used in machine tools to connect the motor to the cutting tool. This allows the cutting tool to operate at a high speed and torque, which is necessary for cutting through tough materials.

- Wind turbines: Rigid couplings are used in wind turbines to connect the blades to the generator. This allows the generator to generate electricity at a controlled speed and torque, which is necessary for providing power to homes and businesses.

- Robotics: Rigid couplings are used in robotics to connect the motor to the robot's joints. This allows the robot to move its joints at a controlled speed and torque, which is necessary for performing tasks such as picking and placing objects.

- Conveyors: Rigid couplings are used in conveyors to connect the motor to the conveyor belt. This allows the conveyor belt to move at a controlled speed and torque.

- Mining: Rigid couplings are used in mining equipment, such as crushers, conveyors, and pumps. The coupling allows the equipment to move materials at a controlled speed and torque, which is necessary for mining operations.

- Construction: Rigid couplings are used in construction equipment, such as excavators, cranes, and loaders. The coupling allows the machinery to move at a controlled speed and torque, which is necessary for construction operations.

- Aerospace: Rigid couplings are used in aerospace applications, such as jet engines and helicopters. The coupling allows the engines to operate at a controlled speed and torque, which is necessary for flight.

Rigid couplings are a versatile and valuable tool for a variety of applications. They can be used to connect 2 shafts that are perfectly aligned, and they can be used in a wide range of industries.

Here are some of the benefits of using rigid couplings:

- Increased efficiency: Rigid couplings can help to improve efficiency by reducing friction and vibration.

- Reduced wear and tear: Rigid couplings can help to reduce wear and tear on the shafts and couplings.

- Improved safety: Rigid couplings can help to improve safety by preventing shafts from becoming misaligned.

- Increased versatility: Rigid couplings can be used in a wide range of applications.

If you need to connect 2 shafts that are perfectly aligned, then a rigid coupling may be the right solution for you.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the maintenance requirements for flexible couplings?

Maintenance of flexible couplings is essential to ensure their reliable and efficient performance over their service life. Proper maintenance helps prevent premature wear, reduces the risk of unexpected failures, and extends the lifespan of the couplings. Here are some key maintenance requirements for flexible couplings:

- Regular Inspection: Perform regular visual inspections of the flexible couplings to check for signs of wear, damage, or misalignment. Look for cracks, tears, or any other visible issues in the coupling components.

- Lubrication: Some flexible couplings, especially those with moving parts or sliding surfaces, may require periodic lubrication. Follow the manufacturer's recommendations regarding the type and frequency of lubrication to ensure smooth operation.

- Alignment Checks: Misalignment is a common cause of coupling failure. Regularly check the alignment of the connected shafts and adjust as necessary. Proper alignment reduces stress on the coupling and improves power transmission efficiency.

- Torque Monitoring: Monitoring the torque transmitted through the coupling can help detect any abnormal or excessive loads. If the coupling is subjected to loads beyond its rated capacity, it may lead to premature failure.

- Environmental Protection: If the couplings are exposed to harsh environmental conditions, take measures to protect them from dust, dirt, moisture, and corrosive substances. Consider using protective covers or seals to shield the couplings from potential contaminants.

- Temperature Considerations: Ensure that the operating temperature of the flexible coupling is within its designed range. Excessive heat can accelerate wear, while extremely low temperatures may affect the flexibility of certain coupling materials.

- Replace Worn or Damaged Parts: If any components of the flexible coupling show signs of wear or damage, replace them promptly with genuine replacement parts from the manufacturer.

- Manufacturer's Guidelines: Follow the maintenance guidelines provided by the coupling manufacturer. They often include specific maintenance intervals and procedures tailored to the coupling's design and materials.

- Training and Expertise: Ensure that maintenance personnel have the necessary training and expertise to inspect and maintain the flexible couplings properly. Improper maintenance practices can lead to further issues and compromise the coupling's performance.

By adhering to these maintenance requirements, you can maximize the service life of the flexible couplings and minimize the risk of unexpected downtime or costly repairs. Regular maintenance helps maintain the efficiency and reliability of the coupling in various industrial, automotive, and machinery applications.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor's life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

Can you explain the different types of flexible coupling designs available?

There are several types of flexible coupling designs available, each with its unique construction and characteristics. These designs are tailored to meet specific application requirements and address different types of misalignment and torque transmission needs. Here are some of the most common types of flexible couplings:

- Jaw Couplings: Jaw couplings consist of two hubs with curved jaws and an elastomer spider placed between them. The spider acts as a flexible element and can compensate for angular and parallel misalignment. Jaw couplings are widely used in various industrial applications due to their simple design and effectiveness in handling misalignment and vibration damping.

- Disc Couplings: Disc couplings use thin metallic discs with a series of alternating slits and flanges to connect the shafts. The disc coupling design allows for excellent misalignment compensation, including angular, parallel, and axial misalignment. Disc couplings are known for their high torsional stiffness and precise torque transmission capabilities.

- Gear Couplings: Gear couplings consist of toothed hubs connected by an external sleeve with gear teeth. They are well-suited for applications with high torque and moderate misalignment. Gear couplings offer good misalignment compensation and high torque capacity, making them popular in heavy-duty industrial applications.

- Beam Couplings: Beam couplings use a single piece of flexible material, often a metal beam, to connect the shafts. The material's flexibility allows for angular and axial misalignment compensation. Beam couplings are compact, lightweight, and provide low inertia, making them suitable for applications with high-speed requirements.

- Bellows Couplings: Bellows couplings consist of a bellows-like flexible structure that connects the two hubs. They can compensate for angular, parallel, and axial misalignment. Bellows couplings are known for their high torsional stiffness and ability to maintain constant velocity transmission.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot. This design allows for angular misalignment compensation while transmitting torque between the hubs. Oldham couplings are often used when electrical isolation between shafts is required.

Each flexible coupling design has its strengths and limitations, and the choice depends on factors such as the application's torque requirements, misalignment conditions, operating environment, and speed. Proper selection of the coupling type ensures optimal performance, efficiency, and reliability in various mechanical systems and rotating machinery.

editor by CX 2023-10-05

China Factory price Coupling Manufacturers Flexible tire coupling fenner drive shaft connector Quick Release fenaflex cohesion and coupling

Guarantee: 1 year

Applicable Industries: Garment Outlets, Building Materials Outlets, Manufacturing Plant, Clamp variety rigid coupling Manufacturing unit Value Very hot Sale Aluminum Alloy shaft connector precision coupling lower inertia Machinery Repair Retailers, Meals & Beverage Factory, Farms, Double elastic diaphragm brake disc coupling SJM variety Factory Price 45# steel flexible shaft connector torque transmission Development works , Strength & Mining, Other

Customized assistance: OEM, Coupling Manufacturer snake spring coupling with brake wheel High Good quality Manufacturing unit Price tag forty five# steel versatile shaft connector ODM, OBM

Structure: UL Sort Tyre Coupling

Adaptable or Rigid: Flexible

Standard or Nonstandard: Standard

Material: Metal

Product identify: LB variety tire coupling

Type: LB

Body Content: 45# Metal

Software: Shaft Connections

Colour: Black

Size: Personalized Dimensions

Surface Therapy: Blackening

MOQ: 1 Established

Certification: ISO9001:2015

Provider: twelve Months

Packaging Particulars: regular export packing and wooden pallets packing

Port: ZheJiang port, China

Business Information

Contact us

Certifications

Our Providers

Packaging & Coupling Maker AMN6 inside friction security coupling torque limiter overload safety Factory Cost Higher Top quality Shipping

Programs

FAQ

Types of Couplings

A coupling is a device that connects two shafts together. It transmits power from one end to another and is used for joining rotating equipment. A coupling is flexible and can accommodate a certain amount of end movement and misalignment. This allows for more flexibility in applications. Various types of couplings are available, and each one serves a specific purpose.

Shaft couplings

There are many types of shaft couplings, and they are used in a wide range of applications. The type you need depends on the torque, speed, and horsepower you need, as well as the size of the shaft and its spatial limitations. You may also need to consider whether the coupling will accommodate misalignment.

Some shaft couplings are flexible, while others are rigid. Flexible couplings can accommodate up to two degrees of misalignment. They are available in different materials, including aluminum, stainless steel, and titanium. They can also be known by different names, depending on the industry. Some couplings can also be used in a single or multiple-shaft application.

The first type of shaft coupling is a rigid coupling, which consists of two parts that fit together tightly around the shafts. These couplings are designed to have more flexibility than sleeved models, and they can be used on fixed shafts as well. The flanged coupling, on the other hand, is designed for heavy loads and is made of two perpendicular flanges. The flanges are large enough to accommodate screws and are generally used with heavy-duty applications.

CZPT shaft couplings are a great choice if you're looking for a shaft coupling that delivers high performance, durability, and low cost. These metal disc-style couplings provide low backlash and high torsional stiffness. Their high misalignment tolerance reduces reaction loads on connected components, which makes them ideal for high-speed precision applications. Available in single and double-disc models, they have torque ratings of up to 2,200 in-lbs. (250N) and are available in fourteen sizes.

When using shaft couplings, it is important to choose the right type for your application. Backlash can cause a shaft coupling to break or become unusable. In order to prevent this from happening, you should replace worn or loose parts, and ensure that the hub and key are evenly positioned with the shaft. If you're using a shaft coupling in a motion-control system, it is important to keep the torque level consistent.

Flexible couplings

Flexible couplings are a type of coupling used to connect two shafts. They are made of rubber or plastic and allow for axial movement of the connected equipment. They do not require lubrication and are resistant to fatigue failure. Flexible couplings are useful for a number of applications. A common type of flexible coupling is the gear coupling, which has gear teeth inside its sleeve. Another type of flexible coupling is the metallic membrane coupling. A metallic membrane coupling is flexible due to flexing metallic discs.

One major disadvantage of flexible couplings is their inability to fit certain types of pipe. This is because most couplings need to be stretched to fit the pipe. This problem is often the result of a change in pipe technology. Traditionally, drain and soil pipe is made of ductile iron or cast iron. Today, most pipes are made of PVC, which has a larger outside diameter than either cast or ductile iron. Because of these changes in pipe technology, many coupling manufacturers have not updated their mold sizing.

Flexible couplings can be either metallic, elastomeric, or a combination of the three. While there are some common characteristics of each type, you should always consider the tradeoffs of each type before choosing one. Generally, the most important considerations when selecting a flexible coupling are torque, misalignment, and ease of assembly and maintenance.

Flexible couplings are used in a wide range of industries. They are useful for connecting two pipes to ensure torque transfer. Although the types available are different, these are the most adaptable couplings in the market. They can withstand movement, vibration, and bending without causing any damage to the piping.

Clutch couplings

A clutch coupling connects two rotating shafts by friction. The clutch engages power when the engine is running, disengaging power when the brake is applied. Clutch couplings are used in applications where the speed of a machine is variable or where continuous service is required. The clutch can transmit power, torque, and axial force.

Clutch couplings come in a variety of styles and configurations. Some couplings are flexible, while others are rigid. Flexible couplings are available in a variety of materials, including stainless steel and aluminum. Some couplings also have a non-backlash design, which helps compensate for misalignment.

Clutch couplings may be synchronous or asynchronous. Synchronous couplings engage and disengage automatically when the driven machine exceeds its output speed. These couplings are synchronized by a synchronizing mechanism. When the output speed is exceeded, the synchronizing mechanism initiates the engagement process. The synchronizing mechanism does not engage or disengage when the output speed drops.

High speed clutches are available from a variety of manufacturers. Some manufacturers offer OEM assembly, repair services, and third-party logistics. These manufacturers serve the automotive, chemical, food, and wood industries, as well as the oilfield and material handling industries. Custom clutches can be manufactured for specific applications and can be fitted with additional features, such as precision machined teeth or keyway slots and grooves.

Couplings are available in PCE, C/T, and metric bores. Typically, the size of the input and output shafts will determine which type of coupling is needed. In addition, clutches may be configured for intermediate or high speeds, depending on the required torque.

Clamped couplings

Clamped couplings are commonly used in a variety of industries. They can be used in medical equipment, dental equipment, military equipment, laboratory equipment, and in precision industrial controls. They are available in a wide variety of sizes and keyways. This type of coupling offers a number of advantages, including ease of installation and quick and easy replacement.

A clamp coupling connects two parts by compressing them together. The clamping elements can be formed in a variety of ways, but they all have a gap between their surfaces. This friction squeezes the two parts together, much like pulling two rubber gloves apart. This type of coupling is also useful for joining two hoses or piping units.

Clamped couplings are designed with a single or double clamping shaft. The clamping parts are mounted in two halves and are held together by eight socket head cap screws. They offer high torque capacity and require little installation space. Their high rigidity ensures good positioning accuracy, making them ideal for dynamic drives. In addition, they are wear-free and offer simple radial assembly.

The invention relates to a method and system for clamping pipes to a tank vessel. This invention also relates to a method of loading and unloading tank vessels. The method can be used in oil production platforms and other platforms. A single point mooring method is also used in oil production platforms.

Clamped couplings can also be flexible. They can join two shafts together while allowing a small amount of end movement and misalignment. These couplings may also be used in the assembly of motors and gearboxes.

CZPT's coupling

CZPT couplings are designed to be flexible, allowing them to accommodate misaligned shafts and transmit torque in either direction. They are made with three discs, two hubs, and a center that are arranged with grooves and fins. These features allow for two degrees of freedom during assembly, and can accommodate misalignment of up to 5% of the shaft diameter.

CZPT couplings have many uses. For example, they can be used to join two parallel coaxial rotating shafts. Their ability to transmit torque at the same rotation mechanism and speed makes them ideal for applications where electrical currents may be a problem. Because the couplings are not made of metal, they are electrically isolated. Designers should test their couplings during the prototype stage to ensure they are working properly.

The CZPT coupling consists of two hubs with one slot on each. An intermediate disk is located between the two hubs. The discs are used to reduce or prevent wear on other machine parts. CZPT couplings are inexpensive and easy to replace. They also have electrical insulation, which makes them easy to repair or replace.

CZPT couplings are a popular choice for stepper motor-driven positioning stages. The plastic center disc offers electrical isolation and absorbs shocks from frequent start/stops. These couplings are available in through-hub and blind-bore styles and can be installed in many applications.

CZPT couplings also allow for small degrees of shaft misalignment. This allows them to function in systems where shaft access is limited. They are easily removed without tools.

editor by czh 2023-03-18

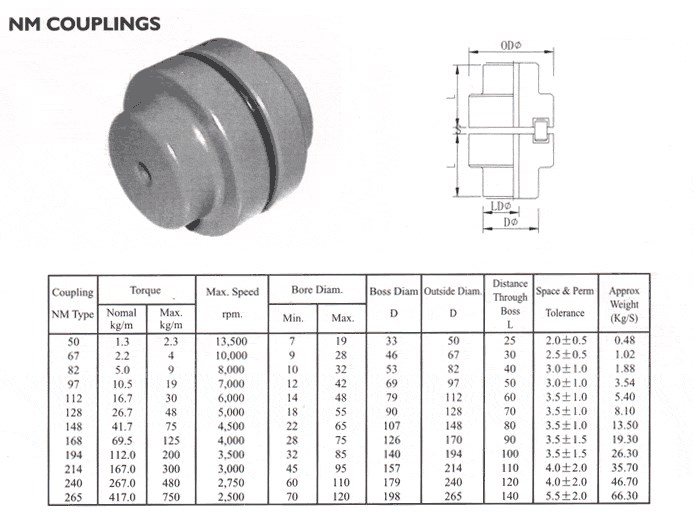

Nm Cheap Coupling Transmission Parts Couplings Rigid Shaft Metal Stainless Steel Tooth Drum Curve Mh Chain Shaft Fexible Type of Rubber Best Manufacturers Nm Coupling with ce certificate top quality low price

Product Description

NM CZPT Transmission Parts CZPT s Rigid Shaft CZPT CZPT Steel Tooth Drum Curve MH Chain Shaft Fexible Type of CZPT Best CZPT rs NM CZPT

Rigid near me shop Coupling Transmission Parts Couplings Shaft Metal Stainless Steel Tooth Drum Curve Nm Chain Shaft Fexible Type of Rubber Best Manufacturers Rigid Coupling with ce certificate top quality low price

Product Description

Rigid CZPT Transmission Parts CZPT s Shaft CZPT CZPT Steel Tooth Drum Curve NM Chain Shaft Fexible Type of CZPT Best CZPT rs Rigid CZPT

Rigid shop Coupling Transmission Parts Couplings Shaft Metal Stainless Steel Tooth Drum Curve Nm Chain Shaft Fexible Type of Rubber Best Manufacturers Rigid Coupling with ce certificate top quality low price

Product Description

Rigid CZPT Transmission Parts CZPT s Shaft CZPT CZPT Steel Tooth Drum Curve NM Chain Shaft Fexible Type of CZPT Best CZPT rs Rigid CZPT